Large Daily Output

Delivery Time: 2025-7-11

Project Name: food factory

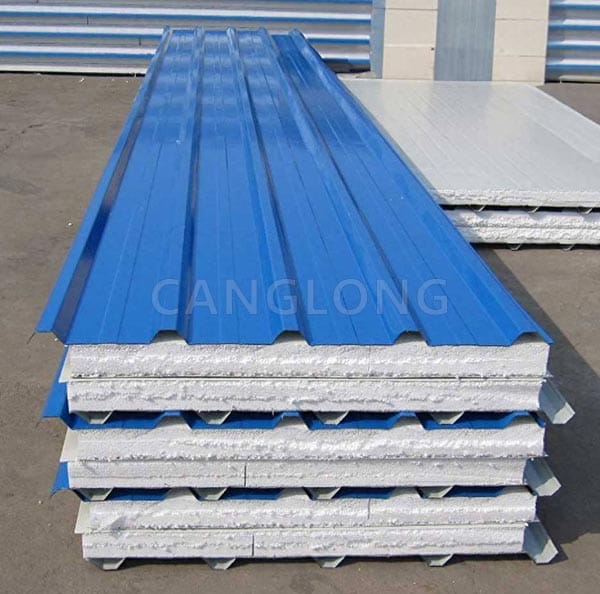

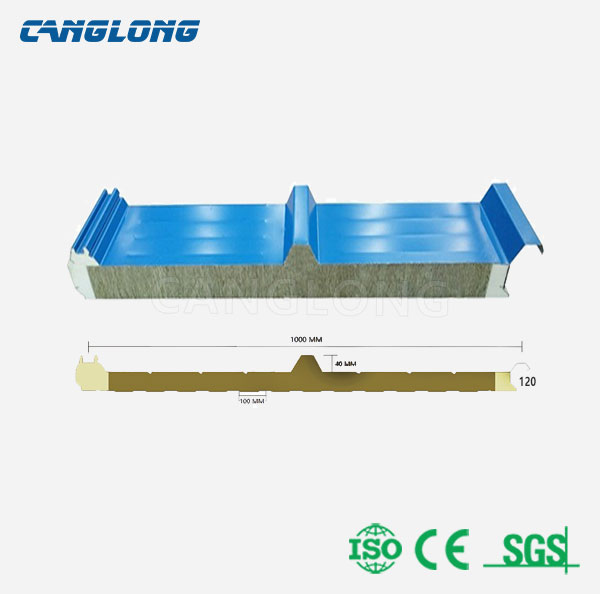

Sea blue puf insulation roof panel shipped to the Philippines

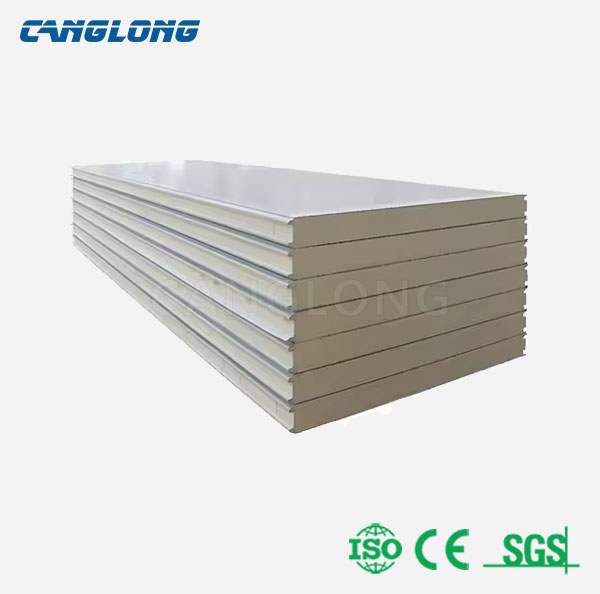

At Canglong Group’s Henan Sandwich Panel Production Base, workers are loading goods for a Philippine customer’s food factory project. This batch of goods includes customized 50mm thick PUF insulated roof panel, as well as matching doors, windows and accessories. After loading, it will set off for Qingdao Port to start a sea journey across the South China Sea.

Behind this batch of orders is the dual demand of Philippine customers for efficient insulation and weather resistance and durability. The customer’s project is a food processing plant that mainly stores tropical fruits, dairy products and cold fresh meat, and has extremely high requirements for the constant temperature and moisture resistance of the workshop. It must not only withstand the Philippines’ average annual high temperature of 28°C (up to 35°C in summer), but also cope with the humid erosion of the rainy season (average monthly rainfall of more than 300mm from June to October), and at the same time match the existing steel frame structure to ensure easy installation.

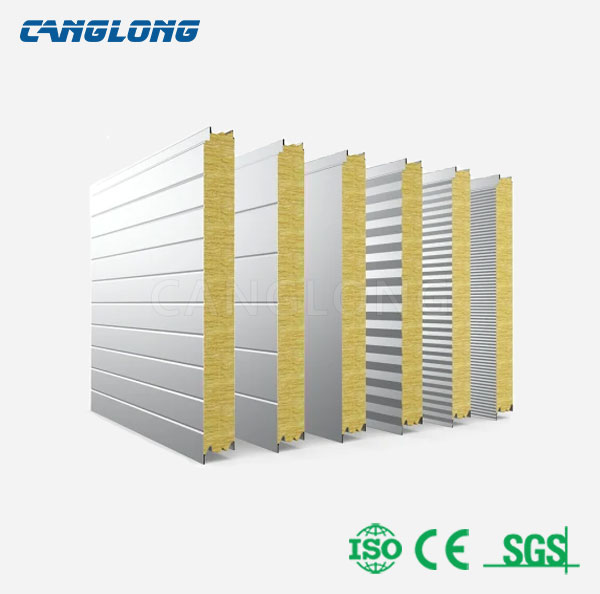

Material selection of puf insulation roof panel

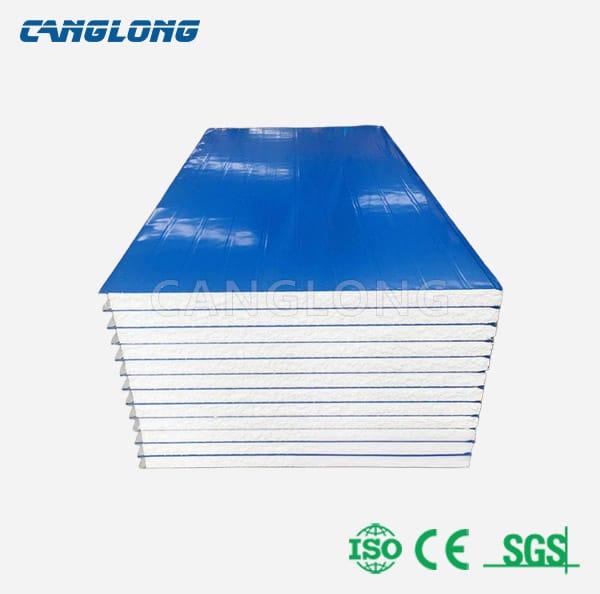

PUF insulation core material: high-density polyurethane with a density of 35kg/m³ (conventional roof panels are mostly 30kg/m³), thermal conductivity as low as 0.022W/(m·K) (30% lower than ordinary rock wool). 50mm thickness can meet the constant temperature requirements of workshop temperature ≤30℃ in summer and ≥15℃ in winter.

Metal sheet: 0.6mm thick aluminum-zinc-coated steel plate is used, the corrosion resistance is twice that of ordinary color steel plate, and the surface is pre-rolled with fluorocarbon coating (salt spray resistance ≥1500 hours), which is suitable for the high humidity and high salt spray environment of the Philippine coast.

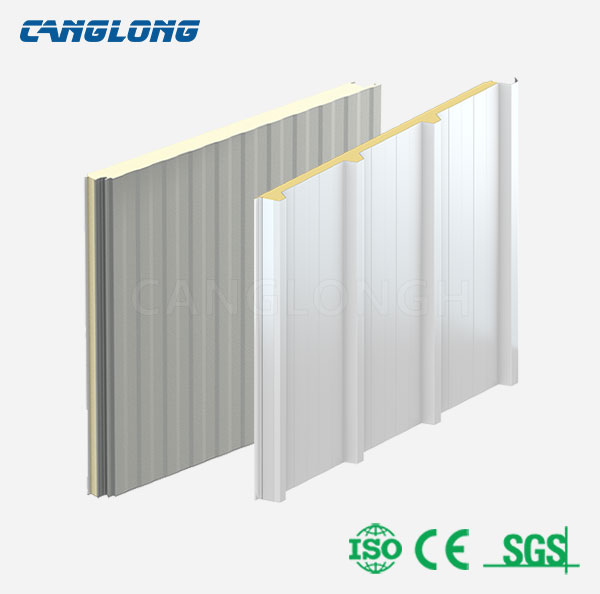

Detail optimization: The wave height of the roof panel is designed to be 35mm (conventional 25mm), the drainage slope is increased (2%), and a customized L-shaped waterproof flashing board (thickness 1.2mm) is matched to prevent leakage from the eaves in the rainy season. At the same time, the panel reserves standard holes (spacing 600mm) and is directly fixed to the customer’s existing steel frame, eliminating the cost of on-site cutting.

After the goods arrive at the Port of Manila, Canglong Group will follow up throughout the process:

- Customs clearance assistance: Provide certificate of origin (FORM E), quality inspection report (including PUF core material density/thermal conductivity test), Philippine BIR certification (import tariff reduction document), and ensure customs clearance within 48 hours.

- Installation guidance: Arrange technical engineers to conduct remote video guidance and demonstration installation videos, focusing on the fixing nodes of PUF panels and steel frames, and the construction techniques of door and window sealants.

- After-sales guarantee: Provide 10-year structural warranty (roof panels) and 5-year coating warranty (metal panels).

Choose Canglong for the best service

Our Shipment

Canglong sandwich panel manufacturer has a complete delivery system, and everything from production completion to packaging and loading will be carried out strictly in accordance with regulations.

Good Raw Materials

Fast Production

Overall Packaging

Fast Delivery

Convenient Unloading

Damage Compensation

Feel free to get in touch

Learn more about this project?