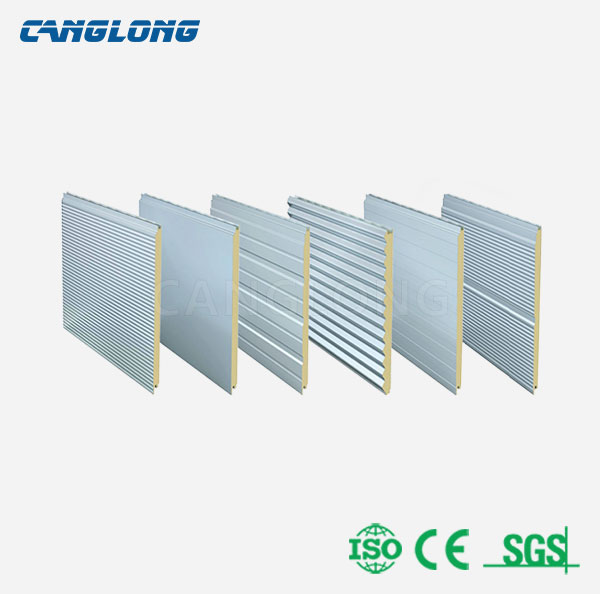

The metal sandwich panels produced by Canglong are sturdy & durable, good insulation effect, fireproof & moisture-proof.

- Date:

2025-7-8

- Project:

warehouse

- Country:

Dominica

- Material:

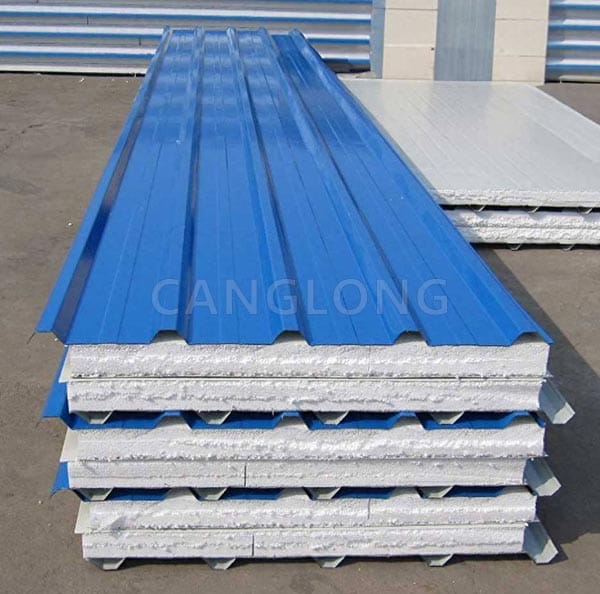

single skin cladding, glass wool

- Tags:

Single skin cladding and glass wool for steel warehouse in Dominica

The sunlight from the Caribbean penetrates through thin clouds and falls on a warehouse construction site in the Dominican Republic. The warehouse project provided by Canglong Group with a one-stop solution has entered the final stage. The gray white roof shines brightly in the sunlight, and the single skin cladding roof is tightly fitted with the glass wool layer filled on the inside, like putting a breathable insulation cap on the warehouse.

Why choose single skin cladding and glass wool for the roof?

The Dominican Republic has a tropical maritime climate with an average annual temperature of 28 ℃, an annual precipitation of over 2000 millimeters, and is frequently affected by hurricanes. If traditional warehouses only use single-layer colored tiles, although they can be quickly built, they are difficult to withstand the triple test of high temperature, high humidity, and strong winds. The heat absorption on the roof during summer causes the temperature inside the warehouse to soar, increasing cooling energy consumption. Rainwater infiltration during the rainy season can easily cause steel structure corrosion, and the wind resistance of a single structure is also insufficient when a hurricane strikes.

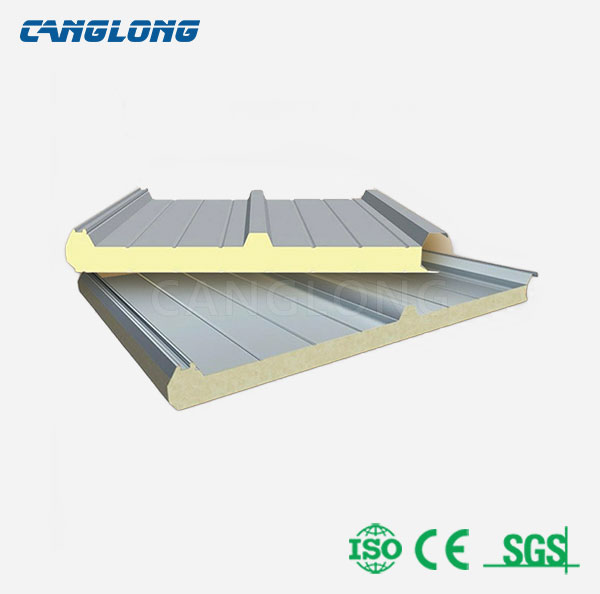

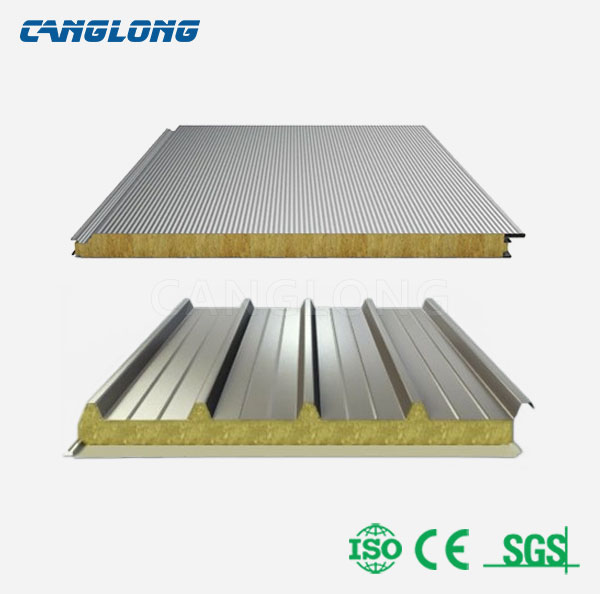

The Canglong technical team innovatively adopts a single skin cladding+glass wool composite roof system based on the local climate characteristics. Using H-shaped steel beams and columns as the skeleton, the beam section is 400mm × 200mm, and the column section is 350mm × 150mm, both of which have been hot-dip galvanized with a galvanized layer thickness of 80 μ m and a wind resistance level of 14. The roof adopts double-layer protection, with an outer layer of 0.5mm thick color steel plate (color customized by the customer as gray white) and an inner layer filled with 80kg/m ³ high-density glass wool (thickness 60mm). The two are tightly fixed by self tapping screws and sealant, forming a composite barrier for structural support and thermal insulation and moisture resistance.

The advantages of single skin cladding and glass wool

- More stable wind resistance: Single tiles are used as the surface layer and are laid in a lap joint manner. Each tile is fixed to the purlin (C-shaped galvanized steel) with 3 self tapping screws, and the screw spacing is strictly controlled within 300mm. The inner glass fiber layer is bonded to the single skin cladding through double-sided aluminum foil veneer, forming a dual guarantee of mechanical fixation and material bonding. Hurricane simulation tests show that the roof system can withstand a level 12 instantaneous wind (wind speed of 32.7m/s), far exceeding the local design standard of level 10 in the Dominican Republic.

- Better insulation: The thermal conductivity of glass wool is only 0.038W/(m · K), which is 1/20 of that of ordinary color steel tiles. According to actual measurements, at noon in summer, the surface temperature of a single tile can reach 65 ℃. However, after being blocked by a glass wool layer, the internal temperature of the warehouse is only 8-10 ℃ lower than the outside (under the same conditions, the temperature difference of a traditional single-layer colored tile warehouse is only 3-5 ℃).

- Moisture resistant for longer: Glass wool has high density and strong hydrophobicity (water absorption rate<1%). Even if a single skin cladding has small cracks due to aging, rainwater will quickly drain away along the tile slope (2%), making it difficult to penetrate into the insulation layer. At the same time, the aluminum foil layer between the single tile and the glass wool can reflect more than 90% of the solar radiation heat, avoiding metal parts from condensing and rusting due to temperature differences.

- Faster installation: The single tile adopts standardized dimensions (1.5m × 1m), which only require bolt fixation on site and do not require complex welding. Glass wool is pre cut into modules that match the roof, glued with a special adhesive, and then covered with aluminum foil waterproof film, without the need for large equipment throughout the process. The project was completed in just 7 days from the completion of the steel structure to the closure of the roof, which is 40% shorter than the traditional process.

Dominican customers not only need warehouses, but also worry free, durable, and cost-effective solutions. The combination of single skin cladding and glass wool is the modular climate solution designed by Canglong for the pain points of tropical storage. It will be further optimized in details such as photovoltaic roofs and ventilation skylights in the future.

Email Us

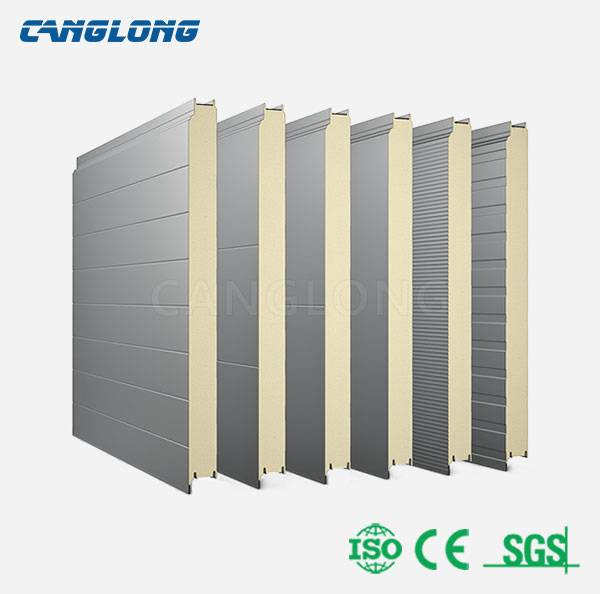

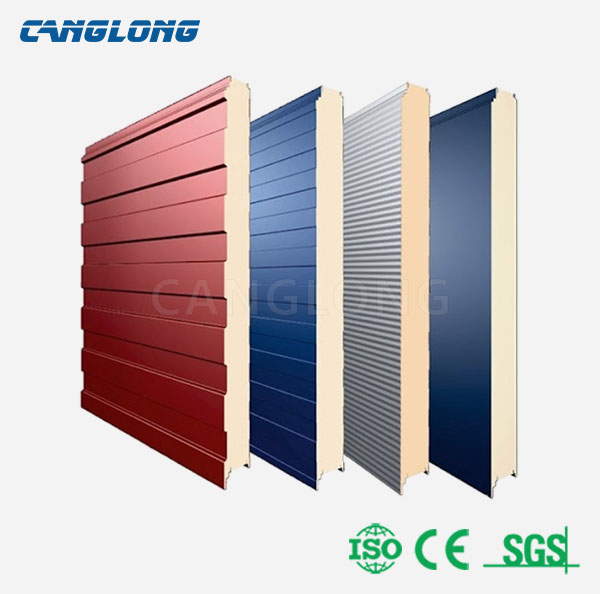

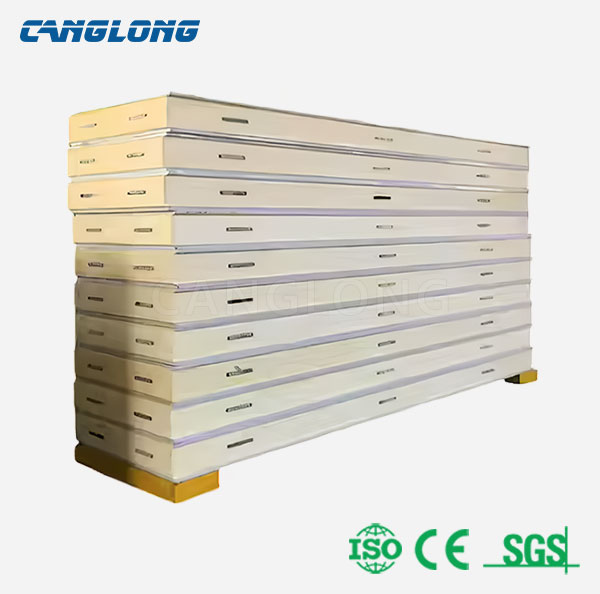

We offer customized polyurethane sandwich panels with a thickness of 30-250mm, suitable for different building needs.

Our comprehensive shipping system ensures strict inspection from production to delivery, guaranteeing timely delivery.

Related Projects & Cases

Indonesia

clean room

Philippines

factory building

Somalia

double slope workshop

Bosnia and Herzegovina

warehouse

Ecuador

cold storage

Philippines