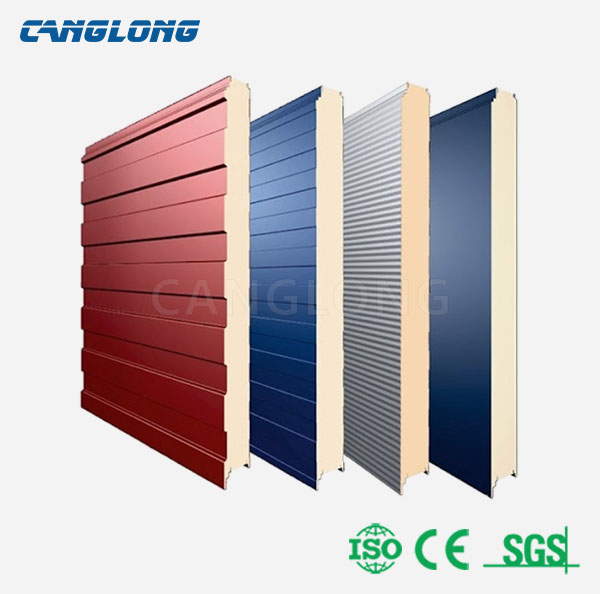

The metal sandwich panels produced by Canglong are sturdy & durable, good insulation effect, fireproof & moisture-proof.

- Date:

2025-6-12

- Project:

warehouse

- Country:

Argentina

- Material:

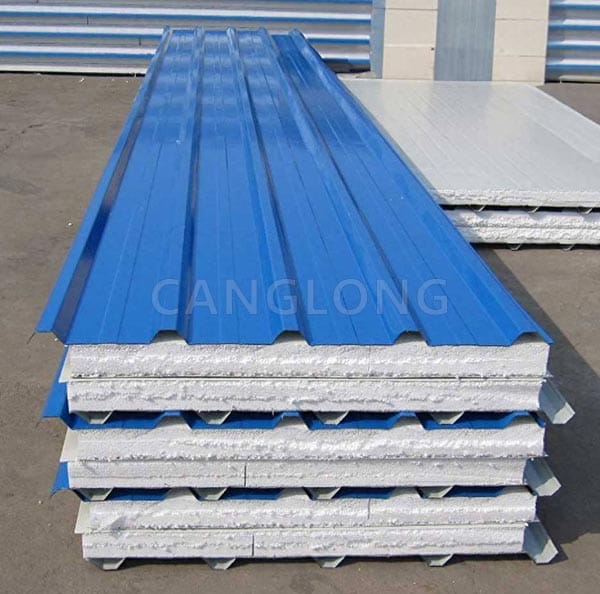

rock wool sandwich panel

- Tags:

Rockwool sandwich panel installation for Argentine steel frame building

In the temperate continental climate of the Pampas in South America, a steel frame building serving the agriculture and manufacturing industry in Buenos Aires, Argentina is under construction. This is a one-stop solution for steel frame and rockwool sandwich panel enclosure tailored by Canglong Group for local owners.

The project adopts Canglong Group’s mature modular steel frame system. The columns and main beams are Q235B grade cold-rolled steel frames, and the surface is hot-dip galvanized (galvanized layer thickness ≥ 275g/㎡). Even in the face of an average of 8-10 strong winds (wind speed exceeding 100km/h) and occasional magnitude 5 earthquakes (Richter 5.5) in the Pampas region of Argentina, the structural stability can still be maintained through flexible node design. All steel components are pre-processed with high precision in Canglong’s Henan factory (cutting error ≤1.5mm, welding flaw detection pass rate 100%). Only bolt connection and quick correction are required on site, which shortens the construction period by 50% compared with traditional cast-in-place structures.

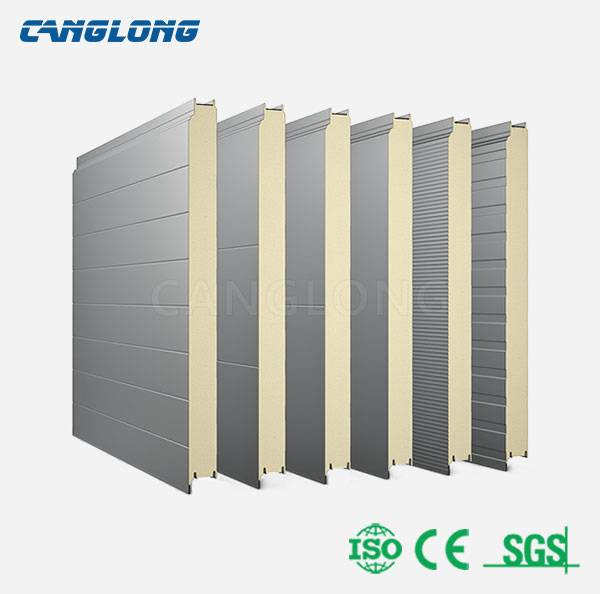

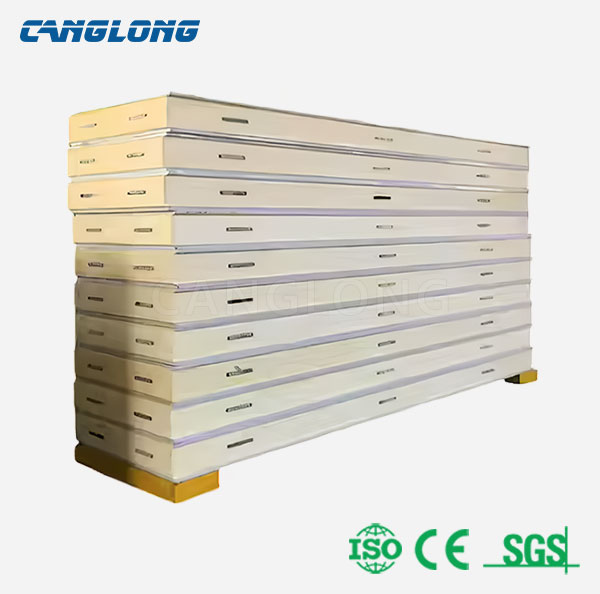

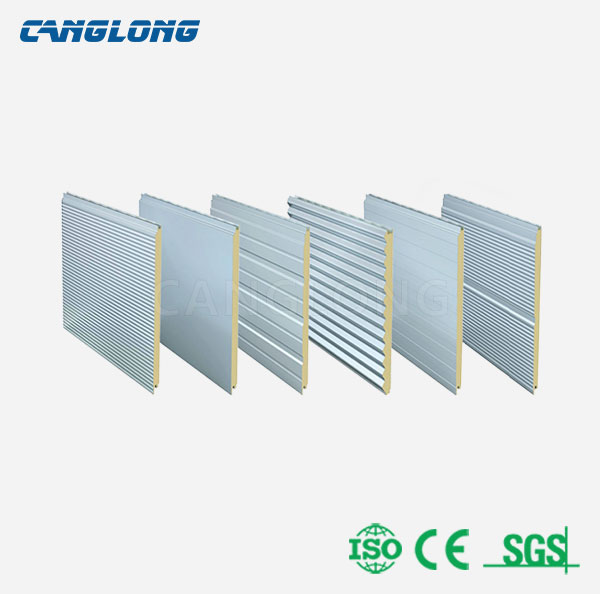

The warehouse wall uses a 50mm thick rockwool sandwich panel (density 120kg/m³, fire rating A1) customized by Canglong, with an outer layer of 0.5mm thick aluminum-zinc steel plate (weather resistance ≥25 years) and an inner layer of moisture-proof aluminum foil. This design not only meets the highest fire protection requirements of Argentina (NCh 1198-2017), but also reduces winter heating energy consumption by 30% through the low thermal conductivity of rock wool (0.040W/(m·K)). The current wall construction has entered a critical stage. The construction team is using the unit hoisting process to quickly splice. The installation of a single sandwich panel only takes 30 minutes, which is 8 times more efficient than traditional masonry.

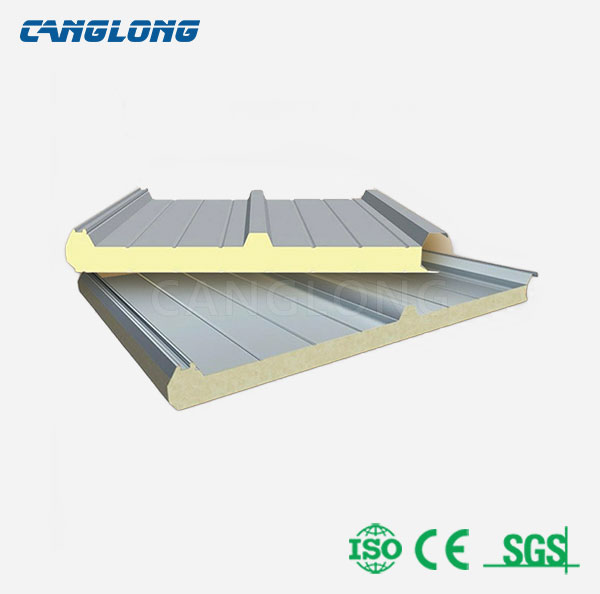

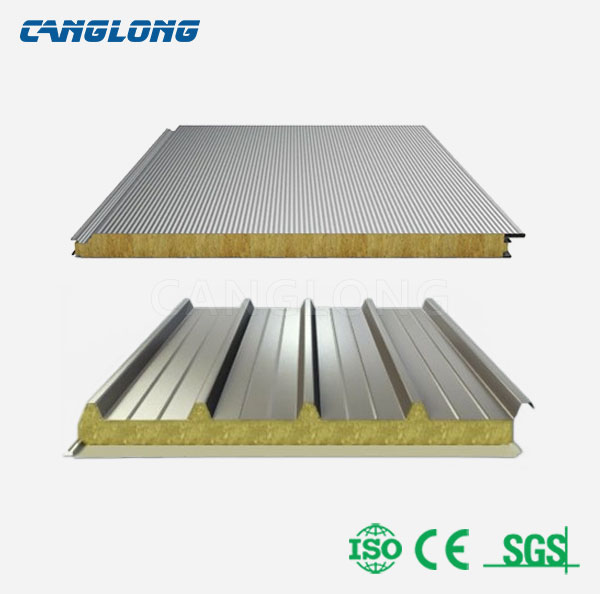

The roof adopts a composite structure of metal plate + waterproof layer. The bottom layer is 1.2mm thick galvanized steel plate (yield strength ≥345MPa), the surface is sprayed with polyester fluorocarbon paint (anti-ultraviolet aging ≥20 years), and is connected with concealed purlins to eliminate the hidden dangers of traditional nailing and leaking. The middle layer is paved with 50mm thick centrifugal glass wool (bulk density 100kg/m³), and the aluminum foil veneer reflects solar radiation heat to reduce the indoor temperature rise caused by heat absorption of the roof in summer. The top layer is covered with gray-white metal plates (thickness 0.8mm), which take into account both aesthetics and weather resistance. In view of the concentrated rainfall of 600mm per year in the Pampas region of Argentina (concentrated in December-February), the roof slope is designed to be 15°, and water guide grooves and PVC downpipes are added to the eaves (drainage efficiency ≥40L/(s·㎡)).

Email Us

We offer customized polyurethane sandwich panels with a thickness of 30-250mm, suitable for different building needs.

Our comprehensive shipping system ensures strict inspection from production to delivery, guaranteeing timely delivery.

Related Projects & Cases

Mongolia

prefab warehouse

Macedonia

steel warehouse

Philippines

cold storage

Indonesia

clean room

America