Large Daily Output

Delivery Time: 2025-5-28

Project Name: clean room

EPS clean room sandwich panel and door sent to Hungary

Recently, Canglong Group successfully completed the shipment of goods for the clean room project of a Hungarian customer. This shipment focuses on three core areas: high specifications, customization, and strict standards, covering 50mm/100mm thick EPS clean room sandwich panel, purification doors, and supporting square tube accessories. This marks the recognition of Canglong Group’s comprehensive service capabilities in the international clean engineering field, injecting new momentum into deepening the layout of the Central and Eastern European markets.

The core materials for this shipment revolve around the clean room enclosure system, and each product has undergone strict design and multiple tests to ensure long-term reliability under local temperature and humidity fluctuations (-10 ℃ to 35 ℃), high humidity (relative humidity 60% -80%), and frequent cleaning and disinfection scenarios in Hungary.

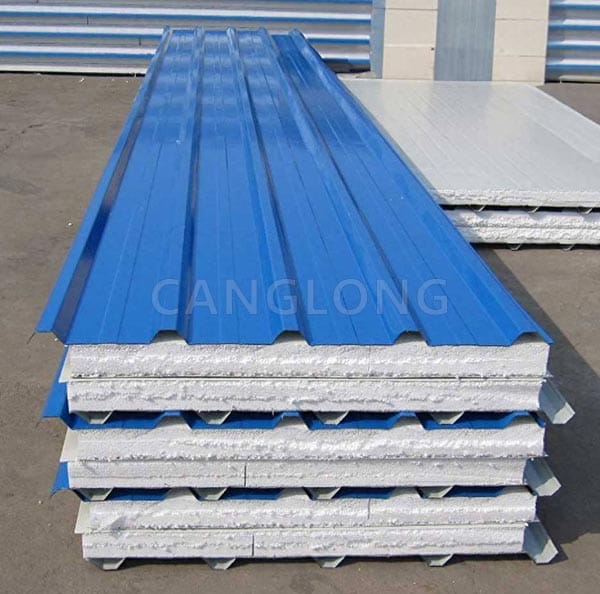

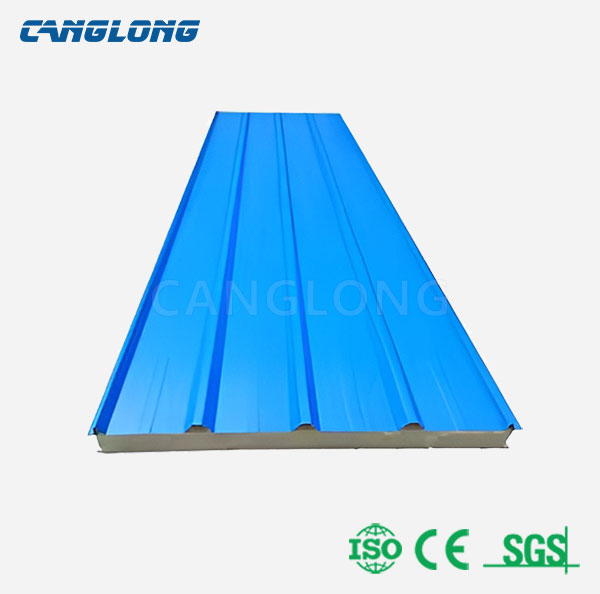

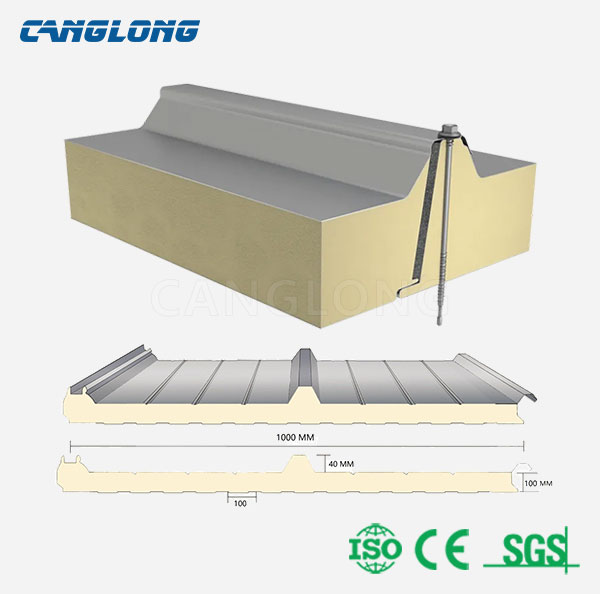

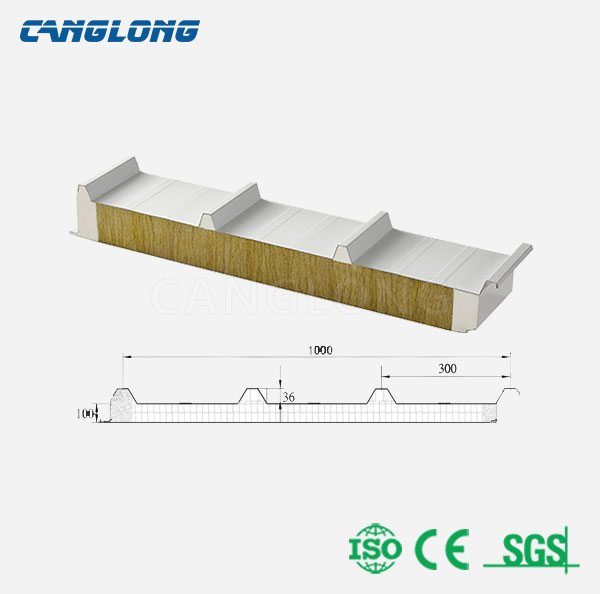

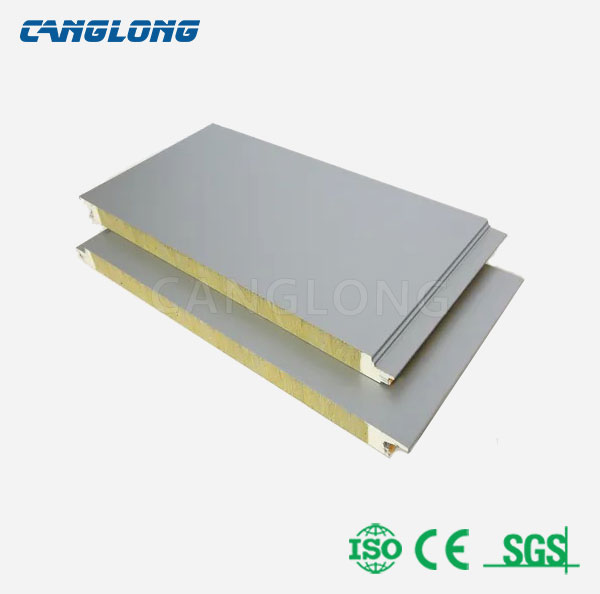

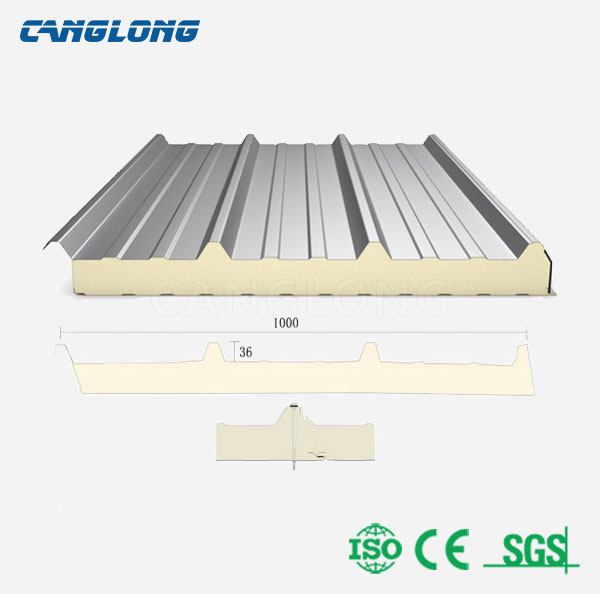

As the wall and top framework of the clean workshop, Canglong Group has customized EPS sandwich panels with two thicknesses of 50mm and 100mm for customers to accurately adapt to the load and insulation requirements of different functional areas.

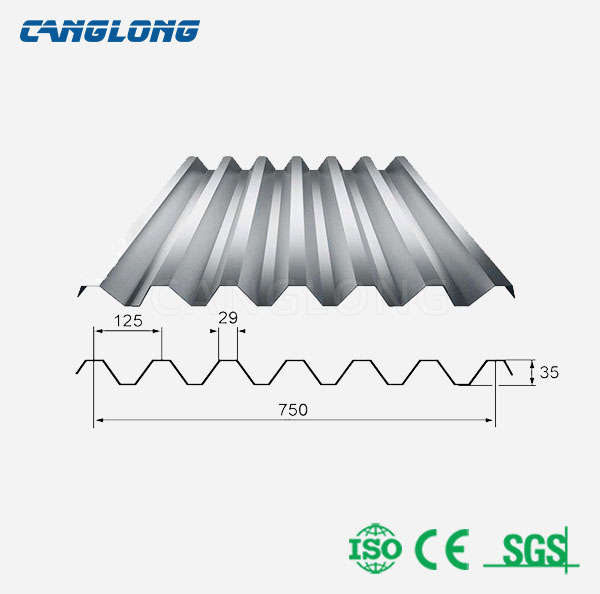

50mm thick clean room sandwich panel: mainly used in non high cleanliness areas such as clean area auxiliary channels and equipment operation rooms. It uses 0.5mm thick aluminum zinc coated color steel plate as the panel (with PE film covering the surface to prevent transportation scratches), with a core material density of 30kg/m ³ and a thermal conductivity coefficient of ≤ 0.038W/(m · K). It ensures lightweight installation (with a weight of about 80kg per square meter) and meets conventional insulation requirements The edge of the board adopts a dual locking process of tongue and seal strips, with a joint gap of ≤ 0.5mm, effectively blocking the penetration of air and dust.

100mm thick clean room sandwich panel: serves as the main material for core production areas such as sterile preparation workshops and electronic clean rooms. The panel has been upgraded to 0.6mm thick stainless steel plate (made of 304 material, resistant to acid and alkali corrosion), with a core material density increased to 40kg/m ³, a thermal conductivity coefficient of ≤ 0.035W/(m · K), and better insulation performance. The overall strength of the board has been tested by a third party to reach 1.2MPa (compressive strength perpendicular to the board surface), which can withstand local pressure during the lifting of large equipment. At the same time, flame retardants are added to the core material, and the combustion performance reaches B1 level (flame retardant), which complies with the EU EN 13501-1 fire protection standard.

All EPS clean room sandwich panels undergo triple quality inspection before leaving the factory, including thickness measurement (with an error of ± 0.5mm), core material density sampling, and fire resistance limit testing (30 minute fire integrity). They are accompanied by EU CE certification and SGS testing reports recognized locally in Hungary.

The supporting purification doors are divided into two specifications: double leaf sliding doors (1.2m × 2.3m) and single leaf swing doors (0.9m × 2.1m), serving scenarios such as isolation between clean and non clean areas and passage through equipment areas.

In terms of material, the panel is made of 1.0mm thick 304 stainless steel (easy to clean and scratch resistant), and the door frame is made of galvanized steel keel and fireproof sealing strip (EPDM rubber, with an aging resistance life of ≥ 15 years).

In terms of performance, the air tightness of the door body reaches Class 4 (ISO 14644 standard, with a particle count of ≥ 0.5 μ m ≤ 10 per cubic meter of air), and when closed, it is matched with a bottom automatic lifting sealing strip (with a stroke of 5mm), effectively blocking cross contamination. The door shaft adopts imported bearings (Nord, Germany), with a switch noise of ≤ 40dB, meeting the low noise requirements of the clean room.

Functionally, some key areas (such as the powder storage room) are equipped with electromagnetic interlocking devices (double door interlocking to prevent airflow disorder caused by simultaneous opening), and integrated observation windows (5mm thick tempered glass, UV resistant coating), making it easy for personnel to observe the internal status without contact.

Choose Canglong for the best service

Our Shipment

Canglong sandwich panel manufacturer has a complete delivery system, and everything from production completion to packaging and loading will be carried out strictly in accordance with regulations.

Good Raw Materials

Fast Production

Overall Packaging

Fast Delivery

Convenient Unloading

Damage Compensation

Feel free to get in touch

Learn more about this project?