Large Daily Output

Delivery Time: 2025-4-25

Project Name: warehouse

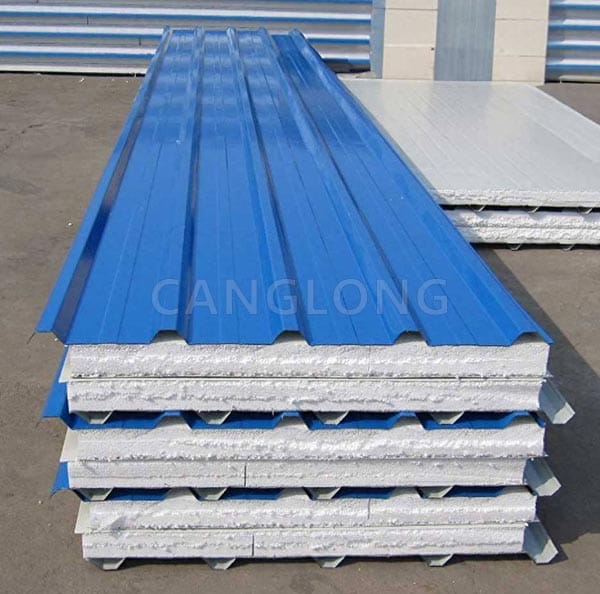

100mm thick insulation rock wool board shipped to Nigeria

Recently, Canglong Group successfully completed the production of 100mm thick insulation rock wool board tailored for a large logistics company in Nigeria, and officially arranged for sea transportation. This order is not only another achievement of Canglong Group’s deepening of the “Belt and Road” international cooperation, but also with the “customization + high specification” product strength, it has injected the reliable guarantee of “China’s intelligent manufacturing” into industrial warehousing projects in high temperature and high humidity environments overseas.

Special needs of Nigerian warehouses: weather resistance, heat insulation, and long-term protection are the key

Nigeria is located in the tropical savanna climate zone of West Africa, with high temperatures (average annual temperature 26-28℃) and high humidity (humidity in rainy season exceeds 80%) throughout the year, and warehouses need to bear a large number of agricultural and sideline products, building materials and other goods for long-term storage, which puts forward strict requirements on the fireproof, moisture-proof and corrosion-resistant properties of wall materials. Although traditional thin sandwich panels (such as 50mm thick) are low-cost, their insulation efficiency is insufficient, and condensation water can easily penetrate due to the temperature difference between the inside and outside, affecting the safety of cargo storage, and if the thickness of ordinary rock wool sandwich panel is insufficient, the structural strength is also difficult to cope with the load requirements of large-span warehouses.

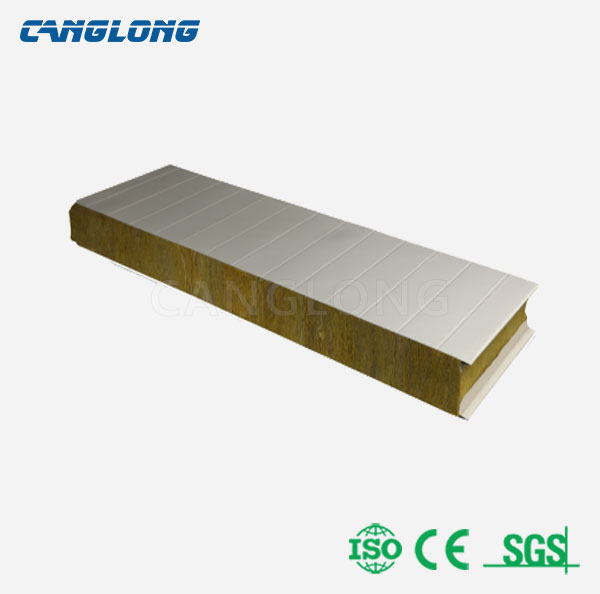

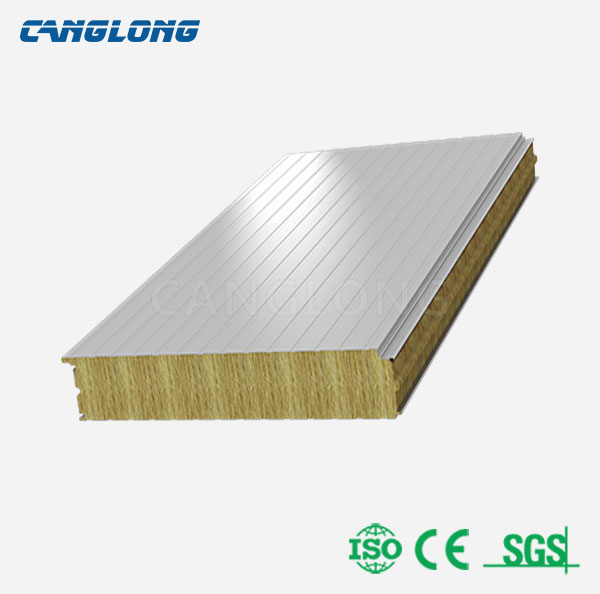

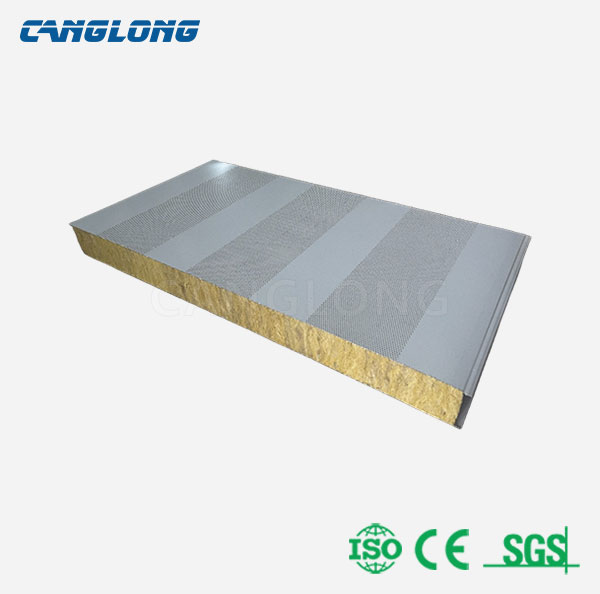

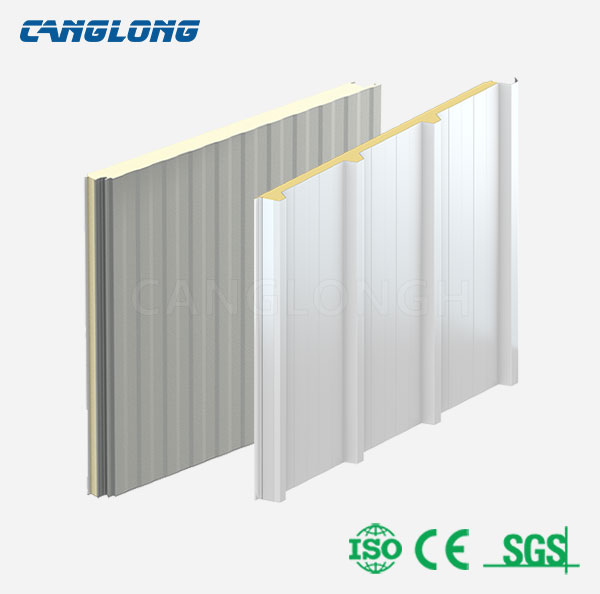

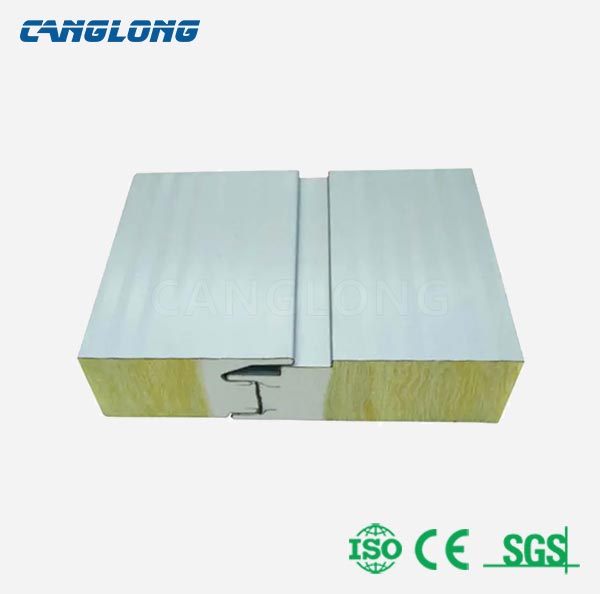

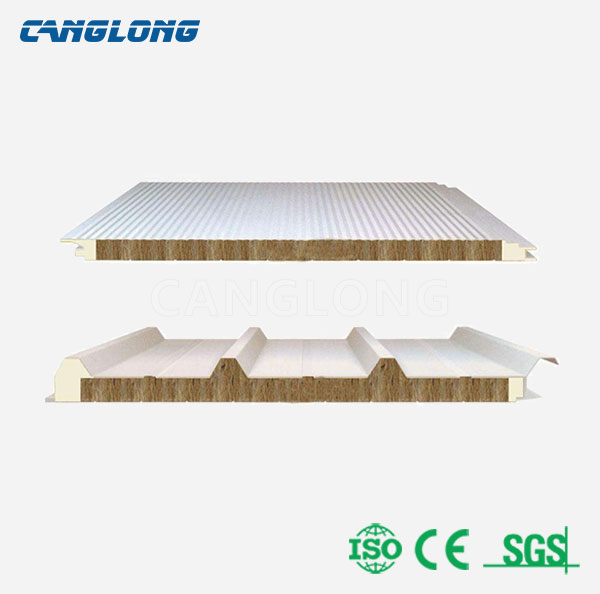

The technical team of Canglong Group conducted in-depth research on customer needs in the early communication, combined with the local climate data and storage scene characteristics of Nigeria, and finally selected a customized solution of 100mm thick rock wool core material + double-sided galvanized steel plate (0.6mm thick):

- 100mm thick rock wool: density reaches 120kg/m³ (higher than the national standard 100kg/m³), thermal conductivity ≤0.04W/(m·K), insulation efficiency is 40% higher than 50mm panels, effectively reducing warehouse air conditioning energy consumption.

- Double-sided galvanized steel plate: zinc content 275g/㎡ (20% higher than the national standard), pre-coated with weather-resistant fluorocarbon paint, salt spray test ≥1500 hours, resisting sea breeze erosion and wet heat rust.

- Reinforcement structure: diamond-shaped steel wire mesh is embedded in the core material to improve the compressive strength of the board surface (up to 1.2kPa) and avoid deformation caused by stacking of goods in large-span storage.

To ensure that the 100mm thick insulation rock wool board meets international transportation and local Nigerian standards, Canglong Group has launched a dual-track process of “customized production + export-level quality inspection”:

- Precise customized production: German TRUMPF laser cutting equipment is used to accurately control the board width (customized according to the warehouse column spacing) and board length (adapted to the size of the transport container). Rock wool filling equipment imported from Italy ensures that the core material density is uniform and there is no hollowing.

- Strict export quality inspection: Each batch of panels must pass the “triple test” – X-ray detection of core material density (error ≤ 2%), salt spray accelerated corrosion test (simulating 5 years of hot and humid environment), static load test (1.5 times the design load without deformation), and finally obtain CE and SGS certification to meet the customs clearance requirements of Nigeria.

- Customized packaging protection: In view of the high humidity and strong turbulence environment of sea transportation, “waterproof film + corner guard plate” double packaging is adopted, and anti-collision strips are pasted on key parts to ensure zero loss of panels in 45 days of sea transportation.

Responding to global customer needs with “Chinese speed”

The smooth delivery of the 100mm thickness insulation rock wool board this time marks the upgrading of Canglong Group’s service capabilities in the field of overseas industrial warehousing. From demand docking, solution design to production delivery, the Canglong team completed the entire process in only 45 days, which is 30% shorter than the industry average cycle. As Mr. Adebayo, the project manager of the Nigerian customer, said: “Canglong not only provides high-performance materials that meet our climate needs, but also allows us to see the reliability of “Made in China” with professional customized services – this is the key to our choice of long-term cooperation.”

In the future, with the deepening of the “Belt and Road” construction, Canglong Group will continue to take “customization, high-end, and globalization” as its direction, and provide more overseas customers with metal sandwich panel solutions that adapt to the local environment, so that “Made in China” materials will become the “safe choice” for global industrial warehousing!

Choose Canglong for the best service

Our Shipment

Canglong sandwich panel manufacturer has a complete delivery system, and everything from production completion to packaging and loading will be carried out strictly in accordance with regulations.

Good Raw Materials

Fast Production

Overall Packaging

Fast Delivery

Convenient Unloading

Damage Compensation

Feel free to get in touch

Learn more about this project?