Southeast Asia cold room panel prices

In Southeast Asia, a region with high temperature and humidity and surging demand for food and cold chain logistics, cold storage construction has become the core infrastructure for fresh food storage and pharmaceutical cold chain. For investors or business owners, the cold room panel prices are not only a key item in the budget, but also directly affects the long-term operating costs and stability of cold storage.

This article will analyze the performance differences and applicable scenarios of cold room panels of different materials in combination with the climate characteristics of Southeast Asia, and focus on recommending high-quality solutions adapted to the Southeast Asian market – cold room panel products of Canglong Group.

Ⅰ. Core influencing factors of cold room panel prices

The price difference of cold room panel is essentially driven by three core factors: thermal insulation performance, durability, and production process. At present, the mainstream cold storage board materials on the market include polyurethane (PU), polystyrene (EPS), and extruded board (XPS). The price and performance differences are significant and need to be selected in combination with specific needs.

1.1. Polyurethane (PU) cold room panel

Polyurethane is the most commonly used insulation material in the cold chain field. Its thermal conductivity is as low as 0.022-0.027W/(m·K), and its insulation performance far exceeds other materials. At the same time, PU panel is formed by on-site foaming process, and the seamless splicing design can effectively block water vapor penetration, which is suitable for the high temperature and high humidity environment in Southeast Asia.

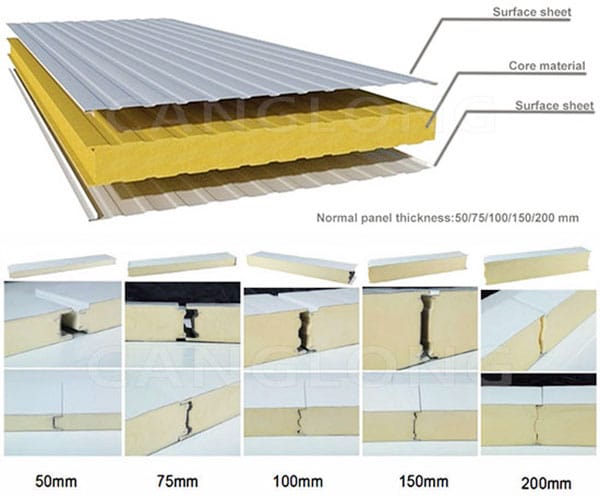

Price range: about $24-$50/㎡ (conventional thickness 50-200mm). The price difference mainly comes from density (40-60kg/m³), flame retardant grade (B1/B2 grade) and panel thickness (color steel plate 0.4-0.6mm).

Applicable scenarios: large cold storage (such as 10,000-ton fresh food storage), pharmaceutical cold chain warehouse, and scenarios with high requirements for insulation efficiency.

1.2. Polystyrene (EPS) cold room panel

EPS panel is made of polystyrene particles with a thermal conductivity of about 0.035-0.045W/(m·K). Its thermal insulation performance is weaker than that of PU panel, but it is cheaper and lighter. However, it has strong water absorption and is prone to expansion and deformation in the high humidity environment of Southeast Asia, requiring additional moisture-proof treatment (such as waterproof film).

Price range: about $16-$30/㎡ (conventional thickness 50-200mm). The price is only 60%-70% of PU board, but the subsequent maintenance cost may be higher.

Applicable scenarios: small cold storage (such as community fresh food stores, temporary storage), limited budget and low requirements for thermal insulation timeliness.

1.3. Extruded Polystyrene Board (XPS)

XPS board is made by continuous extrusion process, with thermal conductivity of about 0.028-0.033W/(m·K), close to the level of PU board, and the closed-cell structure makes its water absorption rate extremely low (≤1%), which is very suitable for humid environment. In addition, XPS board has high strength and good compression resistance, which is suitable for heavy-load scenarios (such as cold storage where forklifts frequently operate).

Price range: about $27-$53/㎡ (conventional thickness 50-150mm). The price is slightly higher than PU panel, but lower than the customized PU with high flame retardant grade.

Applicable scenarios: industrial-grade cold storage (such as cold chain logistics center, low-temperature processing workshop), high humidity or ground water-permeable environment.

Ⅱ. Guide to selecting cold room panel materials in Southeast Asian climate

The average annual temperature in Southeast Asia is 25-35℃, and the relative humidity is 70%-90%. Some areas (such as Indonesia and the Philippines) also have problems with heavy rainfall and salt spray corrosion. In this environment, the moisture resistance, aging resistance, and long-term thermal insulation stability of the cold storage board are key.

2.1. Give priority to composite materials with high thermal insulation and moisture resistance

Ordinary EPS panels are prone to condensation in the high humidity environment of Southeast Asia due to their strong water absorption, which leads to thermal insulation failure and structural damage. The thermal insulation performance of cold room for more than 5 years may drop by more than 30%. PU panels and XPS boards are more suitable for long-term use due to their low water absorption (PU≤3%, XPS≤1%). Among them, high flame retardant PU panels (B1 grade) are the first choice for large cold storage because their fire resistance meets the building specifications of most countries in Southeast Asia (such as Singapore BCA standards).

2.2. Size adaptation

The construction of cold room in Southeast Asia often faces site restrictions (such as narrow alleys and low-rise factories), so the width and length of cold room panels need to be flexibly adapted. The mainstream sizes are 1m and 1.15m in width (convenient for manual handling), and the length can be customized according to the design of the warehouse (commonly 6-12m). Leading enterprises such as Canglong Group support non-standard customization, and can adjust the board type according to the special site requirements of Southeast Asian customers to reduce installation costs.

Ⅲ. Advantages of Canglong Group

In the Southeast Asian cold room panel market, enterprises not only need to provide suitable materials, but also need to solve the pain points of localized services and cost control. As an enterprise that has been deeply involved in cold chain facilities for 15 years, Canglong Group has become the preferred choice of Southeast Asian customers with the following advantages:

3.1. Full material coverage to meet different budget requirements

Canglong Group can produce cold room panels of three mainstream materials: PU, EPS, and XPS, and launch a moisture-proof enhanced version series for the Southeast Asian market. For example, adding a waterproof coating to the surface of the PU panel, or adding moisture-resistant fibers to the EPS panel, the water absorption rate will be reduced by more than 50%, and the price is only 10%-15% higher than the conventional version, and the cost performance is far superior to similar products.

3.2. Customized services to adapt to complex scenes in Southeast Asia

For the small site and multi-scenario needs of cold storage in Southeast Asia (such as fishing port cold chain and mountain plantation cold storage), Canglong Group provides size customization and structural optimization services. For example, a 1m wide ultra-narrow board type was designed for a cold storage in a fishing port in Indonesia, and the modular installation process was used to shorten the construction period by 30%. Fireproof B1-grade XPS boards were customized for tropical fruit storage warehouses in Thailand, taking into account moisture-proof and typhoon-resistant performance.

3.3. Supply chain advantages, reducing overall costs

Canglong Group has a 46,000 square meter production base, with 5 PU panel production lines, 3 EPS panel production lines and 2 XPS board production lines. It has strong production capacity, can deliver quickly, and ensures that product quality meets international standards (such as ISO 9001 certification). According to calculations, the cold room panel prices of the same specifications in the Southeast Asian market is 20%-30% lower than that of European brands.

Ⅳ. Conclusion

For cold storage builders in Southeast Asia, the cold room panel prices are not the lower the better. Low-priced EPS panels may increase costs due to frequent maintenance, while highly adaptable PU or XPS boards, although with high initial investment, can reduce energy consumption and maintenance expenses through long-term stable thermal insulation performance. With the advantages of full material coverage and customized services, Canglong Group provides Southeast Asian customers with cost-effective and reliable cold storage board solutions, helping cold chain projects to be built quickly, used for a long time, and save more.

If you are planning a cold storage project in Southeast Asia, you may wish to contact Canglong Group to obtain a free “material selection + cost calculation” solution to make every investment worthwhile!