Fire safety standards and classifications for rockwool insulation board in buildings

Amid the growing emphasis on energy conservation and sustainable development, rockwool insulation board has become one of the most popular Class A fireproof insulation materials for building envelopes due to their excellent thermal insulation properties, chemical stability, and inherent non-combustibility.

However, fire safety requirements for rock wool insulation boards vary significantly across countries and regions due to differences in climate, building codes, and fire risks. This article systematically reviews the fire safety standards for rockwool insulation board in core global markets, analyzes their classification logic, and provides a compliance reference for construction professionals based on practical application scenarios.

I. The Fire Risks of Rockwool Insulation Board

Rock wool is an inorganic material made from natural rocks (such as basalt and dolomite) through high-temperature melting and fiberization. Its theoretical combustion performance is non-combustible (Class A), with a melting point exceeding 1000°C and the absence of combustible organic components (such as plastics and asphalt). However, it is important to note that non-combustibility does not necessarily mean absolute fireproofing. The safety of rock wool products also depends on the overall structural design, installation process, and heat release behavior in fire scenarios (such as shrinkage and smoke generation at high temperatures).

In building fires worldwide, fire spread in external insulation systems is a major cause of casualties. Therefore, fire safety standards in various countries focus not only on the combustion performance of the material itself but also on system-level fire protection capabilities (such as flame spread, heat release rate, and smoke toxicity) to ensure that buildings provide time for evacuation and rescue in the event of a fire.

II. Fire Safety Standards in Core Markets

While standards in different countries/regions have different focuses, their core principles all revolve around restricting the use of combustible materials and controlling fire spread. The following are the three most influential standards globally:

1. China: GB 8624-2012

China was one of the first countries in the world to implement mandatory fire protection standards for external thermal insulation in buildings. According to GB 8624, building materials are classified into five grades based on their combustion performance: A1, A2, B1, B2, and B3 (Grade A is non-combustible and Grade B3 is flammable). Due to its compositional properties, rockwool insulation board can theoretically achieve A1 or A2 grades, but actual grading requires passing two core tests:

Burning drips/particles: Grade A1 requires no ignition of filter paper by flaming drips, while Grade A2 allows for a small amount of dripping but does not ignite the filter paper.

Gross calorific value (THR₆₀₀ₛ): Grade A1 ≤ 2.0 MJ/kg, Grade A2 ≤ 3.0 MJ/kg. Rock wool’s THR is typically <1.0 MJ/kg, well below the limit.

System-level requirements: China’s GB 50016-2014 specifies that residential buildings with a height greater than 27 meters and public buildings with a height greater than 24 meters must utilize Class A flammability-resistant materials (such as rock wool) for their exterior wall insulation systems. For crowded spaces (such as hospitals and schools), the use of Class A materials is mandatory, even for lower-rise buildings.

2. EU: EN 13501-1:2018

The EU uses a single grading system (A1, A2, B, C, D, E, F), with A1 being completely non-flammable, A2 being nearly non-flammable, and B-F being flammable (B being the least flammable, F the most flammable). Rockwool insulation board typically pass the following tests to obtain their grades:

EN 13823 (Single-Body Burning Test): This simulates a real-world fire scenario and evaluates the material’s flame spread, heat release rate (HRR), total heat release (THR), and smoke development (SDR). Grade A2 requires a total heat release of ≤3 MJ within 600 seconds, with flames not spreading to the edges of the specimen.

Additional requirements of EN 13501-1: Grade A1 also requires stricter requirements, such as the absence of flaming dripping and a combustion growth rate index (FIGRA) of ≤0.1 MJ/s.

System Verification: The EU CPR requires that external insulation systems undergo comprehensive fire testing to verify their fire resistance in real buildings. This includes preventing flames from penetrating the main structure and limiting the release of smoke and toxic gases.

3. United States: ASTM E84 and NFPA 285

US fire protection standards focus on surface burning performance and system flame spread risk:

ASTM E84 (Flame Spread Index (FSI) and Smoke Density Index (SDI)): Materials are classified into three grades: A (FSI ≤ 25, SDI ≤ 450), B (FSI 26-75, SDI ≤ 450), and C (FSI 76-200, SDI ≤ 450) (no D/E/F grades exist). Rockwool, due to its non-combustibility, generally receives the highest grade, A.

NFPA 285, “Flame Propagation Tests for Exterior Insulation and Finish Systems,” requires that for buildings 40 ft (12.2 m) or taller, flames of exterior insulation systems must not spread beyond 30 inches (0.76 m) above the base of the specimen under a simulated window fire attack, with a total heat release of 300 MJ or less. This standard specifically focuses on the fire performance of interfaces between different materials, such as the compatibility of rock wool with metal studs and sealants.

III. Classification of Rockwool Insulation Board

Based on global standards, rock wool insulation panel can be classified based on their combustion performance and application scenarios.

1. Classification by Combustion Performance

Class A1 (Completely Non-Combustible): Applicable to all building heights and crowded locations (e.g., China GB 50016, EU EN 13501-1 Class A1). Typical applications include high-rise residential buildings, hospitals, schools, and transportation hubs.

Class A2 (almost non-combustible): Suitable for low-rise and multi-story buildings (e.g., residential buildings ≤27m tall and public buildings ≤24m tall in China; EU Class B1-B buildings), or as a supplement to Class A1 materials (e.g., insulation in non-critical areas).

2. Classification by Application

Exterior Insulation Systems (EIFS): Must meet system-level fire protection requirements (e.g., China GB 50016, EU EN 13381-4, US NFPA 285), focusing on flame spread, heat release rate, and adhesion to the base wall.

Roofing Insulation: In addition to fire protection, it must also meet waterproofing and compressive strength requirements (e.g., US ASTM D3909). Some countries (e.g., Germany) require roofing rockwool to pass rain impact testing to prevent water absorption from compromising fire resistance.

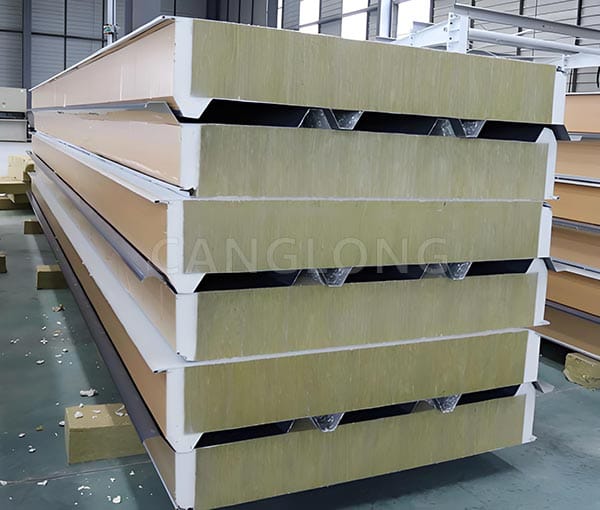

Sandwich panels/metal composite panels: Used in industrial plants, warehouses, and other areas, they must meet structural fire protection requirements (e.g., fire resistance ≥ 1h) and wind-uplift resistance (e.g., US UL 2218). The rock wool core must be bonded to the metal panels with a weather-resistant adhesive to prevent delamination under high temperatures.

IV. Safety Key Points in Practical Applications

Even if rockwool insulation board meet the highest standards, their safety still depends on careful attention to the following details.

Installation Procedure: Anchors must be made of stainless steel or galvanized steel to prevent rust and fall-off, with spacing ≤ 600mm. The bonding area must cover ≥ 50% (Chinese standards) or ≥ 40% (EU standards) to ensure a seamless connection with the underlying wall.

Joint Treatment: Joints between panels must be filled with a fire-resistant sealant (e.g., silicone sealant) to prevent gaps from becoming chimneys and accelerating the spread of fire. Fire barriers must be installed at the junctions of different materials (e.g., between rock wool and door and window frames). The width must be ≥ 500mm and the material must be Grade A.

Maintenance and Management: Regularly inspect rock wool for signs of pulverization or shedding due to aging (pulverization increases dust concentration and may increase smoke and toxic risks), and promptly repair damaged areas.

V. Future Trends

Global building standards are evolving from a single focus on fire protection to multiple objectives: fire protection, low carbon emissions, and sustainability. For example:

The EU Energy Performance of Buildings Directive (EPBD) requires that all new buildings after 2030 be zero-carbon. Rock wool remains the preferred material due to its low production energy consumption (only one-third of EPS) and recyclability (recycling rate >90%).

China’s “Dual Carbon” policy is driving the rock wool industry towards low-carbon rock wool (using industrial waste to partially replace ore raw materials) and ultra-light, high-strength rock wool technologies, while also strengthening the coordinated design of fire protection and energy conservation.

Conclusion

The fire safety performance of rockwool insulation board is their core competitive advantage as an energy-saving building material. However, their safety requires a comprehensive approach through material grading, system verification, and standardized installation. While standards vary across regions, they are all based on scientific testing and prioritize human safety.

For construction professionals, a thorough understanding of local standards and strict control of installation details are key to leveraging rock wool’s non-combustibility advantages and ensuring building safety. In the future, as technology advances and standards are upgraded, rock wool insulation panels will continue to serve as a benchmark material for green fire protection and play a vital role in the sustainable development of global buildings.