Large Daily Output

Delivery Time: 2025-5-21

Project Name: cold room

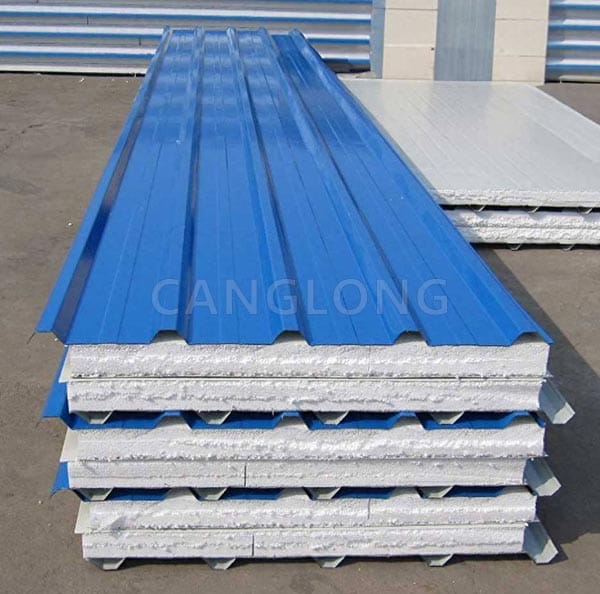

Shipment of 150mm pir coolroom panels to Belgium

Recently, the cold storage project tailored by Canglong Group for Belgian customers has been successfully prepared and is about to be shipped. As an important practice for Canglong Group to deepen its layout in the European market, this project implements the service concept of precise adaptation, efficiency and reliability from demand docking to implementation, and builds a low-temperature storage system for customers that takes into account both performance and efficiency.

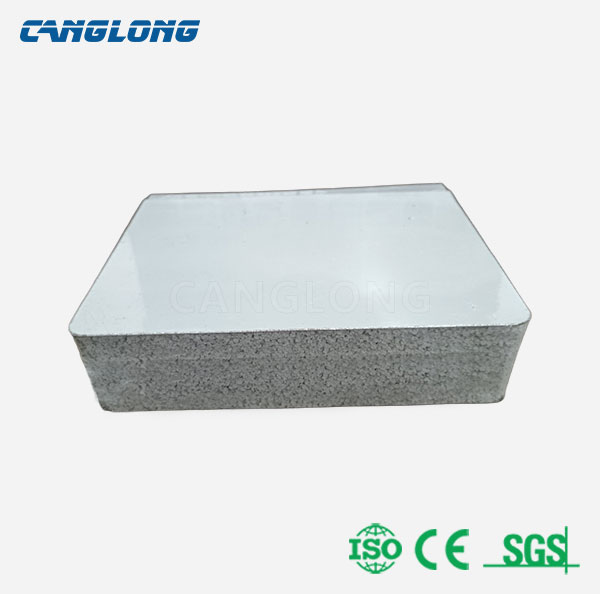

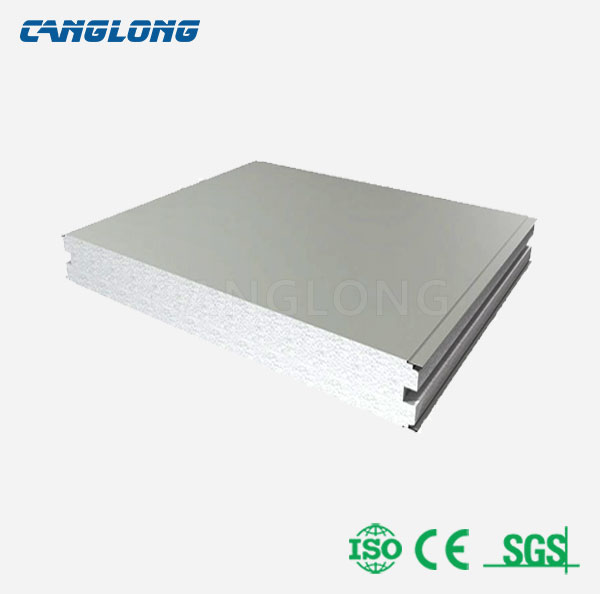

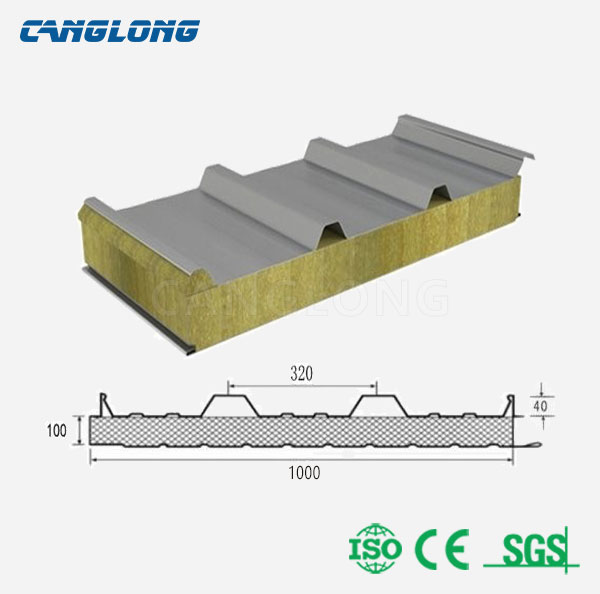

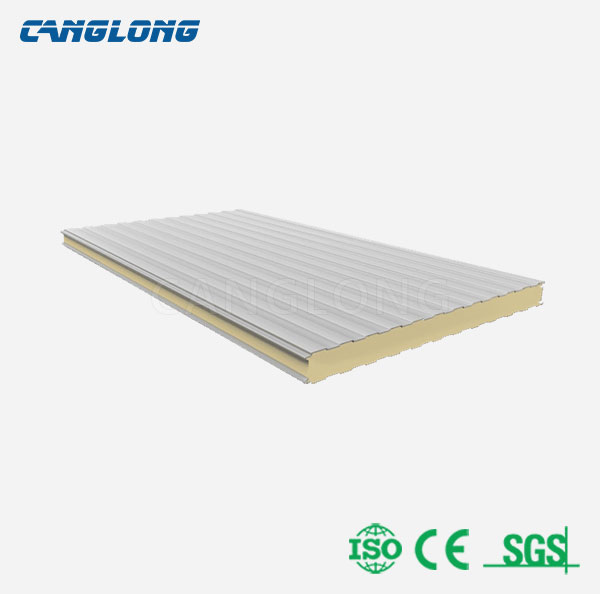

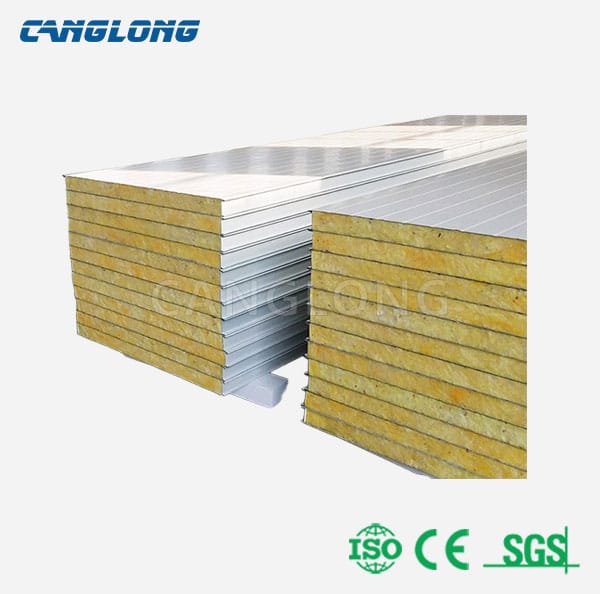

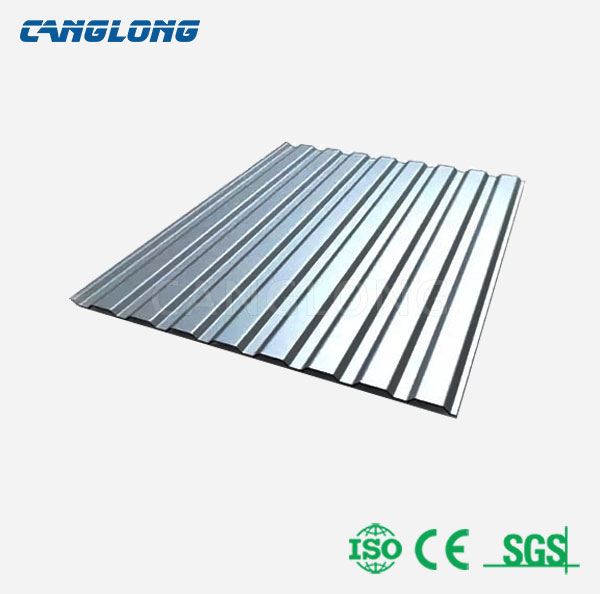

The core products supplied this time include 150mm thick PIR coolroom panels. The panel adopts a high-density foaming process, with a thermal conductivity as low as 0.022W/(m·K), and is packaged with double-sided color steel plates or stainless steel plates. It has excellent thermal insulation performance and structural strength, and can meet the strict temperature stability requirements of cold chain storage in Belgium.

The customized cold storage door delivered simultaneously is optimized according to the project site size and usage scenarios, equipped with dual-temperature zone sealing strips and explosion-proof locks to ensure that there is no loss of cold during the opening and closing process, effectively extending the overall operation efficiency of the cold storage.

In addition, more than ten types of auxiliary materials required for the project, such as thermal insulation sealant, auxiliary pipelines of the refrigeration system, and loading and unloading platform components, are configured according to the EU CE certification standards, forming a complete supporting system from the main structure to the details.

In order to ensure the integrity and timeliness of cargo transportation, the logistics team of Canglong Group adopts the “moisture-proof film + cushion” multi-layer protective packaging solution. EPE pearl cotton corner guards are added to the vulnerable corners of the pir coolroom panels, and the transportation vibration scene is simulated through three-dimensional modeling to optimize the bundling and fixing method.

At present, all goods have completed the warehouse verification and are being packed by a professional team according to the principle of first urgent and then slow, and classified stacking. It is expected to be sent to Belgium via the China-Europe Express special line. The full-process tracking system will synchronize the logistics nodes in real time to ensure that customers receive and install the project on time.

Choose Canglong for the best service

Our Shipment

Canglong sandwich panel manufacturer has a complete delivery system, and everything from production completion to packaging and loading will be carried out strictly in accordance with regulations.

Good Raw Materials

Fast Production

Overall Packaging

Fast Delivery

Convenient Unloading

Damage Compensation

Feel free to get in touch

Learn more about this project?