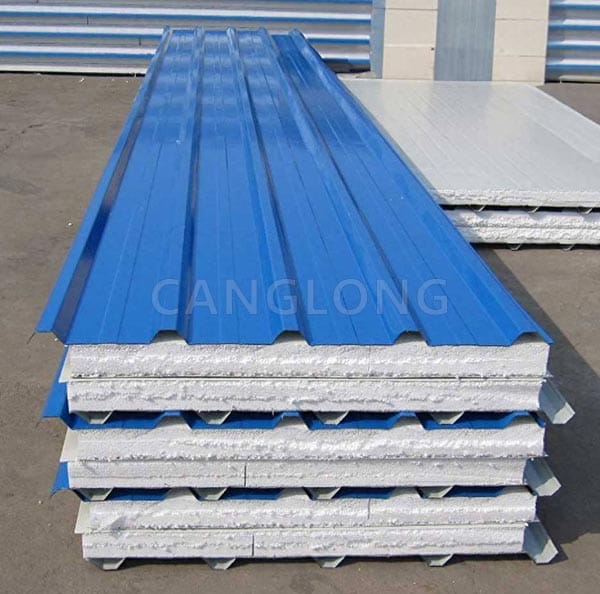

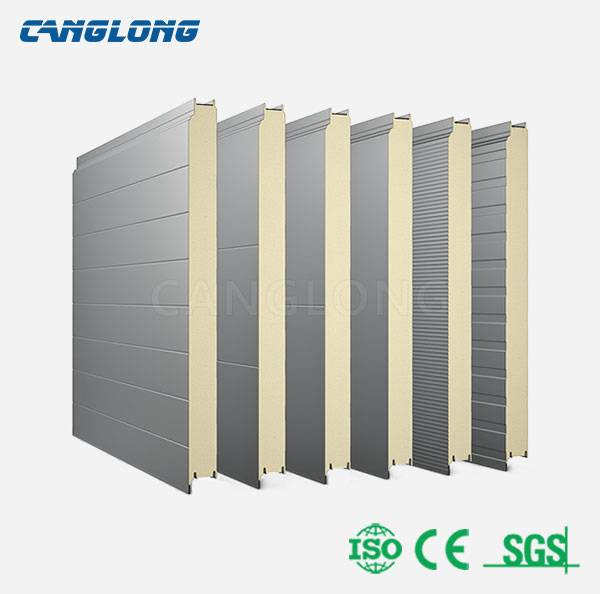

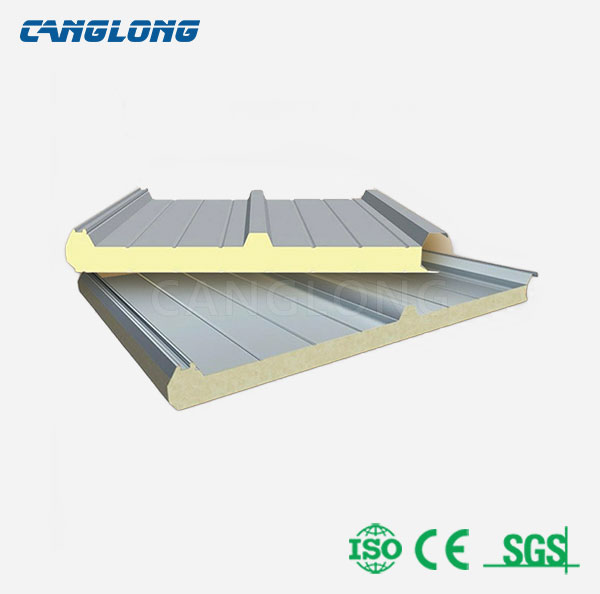

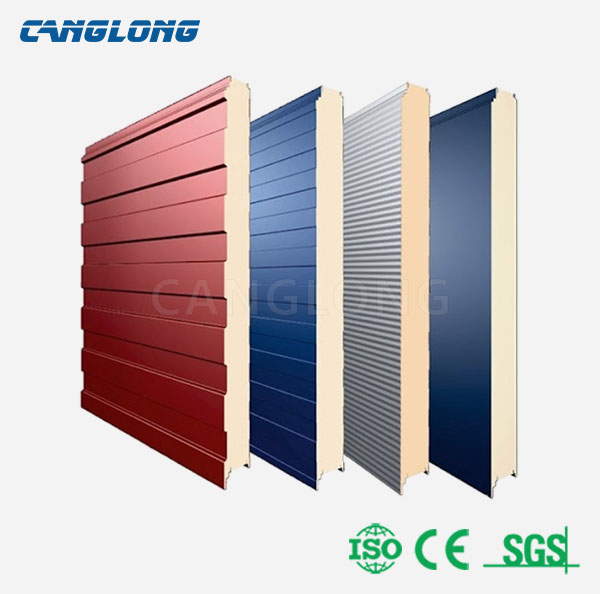

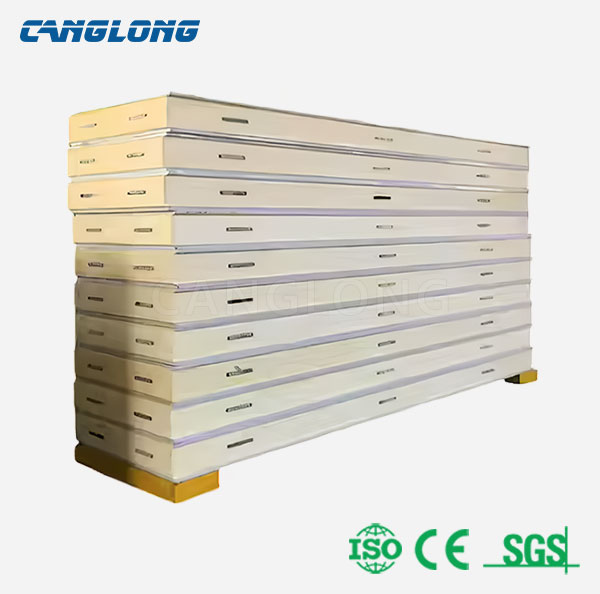

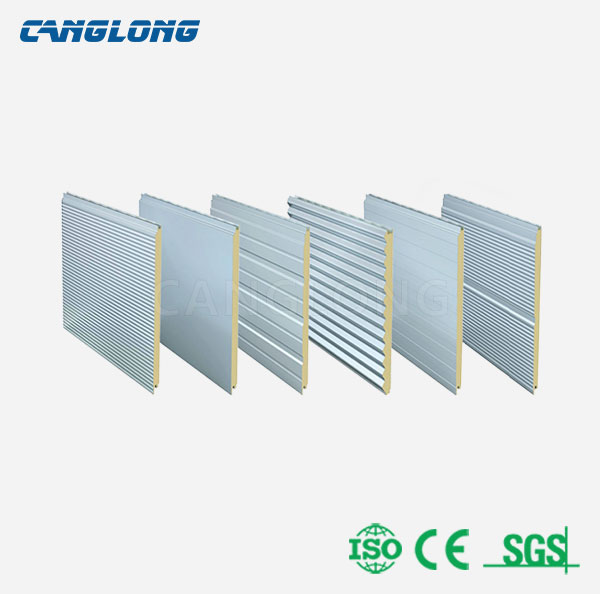

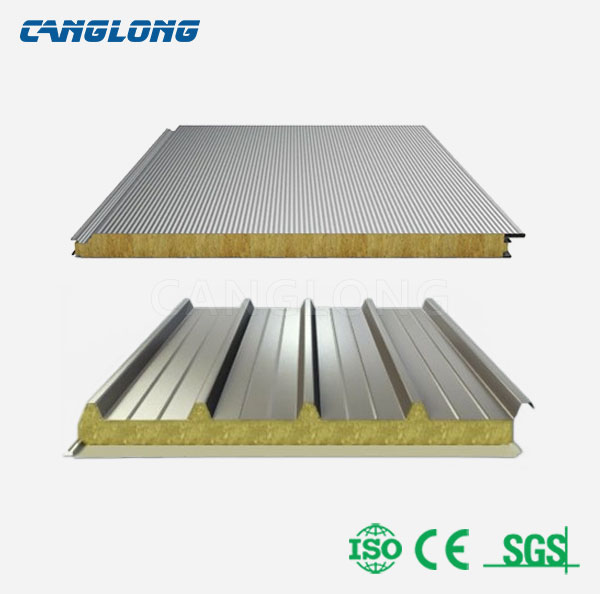

The metal sandwich panels produced by Canglong are sturdy & durable, good insulation effect, fireproof & moisture-proof.

- Date:

2026-1-22

- Project:

warehouse

- Country:

Trinidad and Tobago

- Material:

color steel plate, metal sheet

- Tags:

Trinidad and Tobago metal godown

Canglong Group leveraging its full-cycle professional capabilities, has built a highly efficient and practical modern warehouse for its clients in Trinidad and Tobago. The metal godown project occupies a regular area, measuring 24.38 meters long and 12.2 meters wide, with a spatial layout that balances storage efficiency and operational convenience. The building height is scientifically planned, with a 6-meter eaves height to meet daily equipment access needs, and an 8-meter roof height optimized for natural lighting and ventilation through a double-slope design. A reasonable 15° slope further facilitates rapid rainwater drainage, effectively reducing the risk of water accumulation.

Regarding structural safety and cost control, the Canglong team selected Q355 high-strength H-shaped steel as the main beams and columns. Their excellent tensile and compressive strength ensures the stability of the large-span space while also offering lightweight advantages. The secondary structure uses C-shaped steel purlins, forming a rigid-flexible support system with the main steel structure, further reducing steel consumption.

The enclosure system of metal godown utilizes color-coated steel panels throughout, combining weather resistance and aesthetics. The matching color scheme of the exterior walls and roof creates a clean and sophisticated look. The matching aluminum alloy windows and industrial-grade roller shutters not only meet daily ventilation needs but also enhance moisture resistance and wind resistance through thickened materials and a sealed design, making them suitable for tropical island climates.

It’s worth mentioning that Canglong provides a complete package delivery service. From concealed engineering components such as gutters and drainage pipes to detailed consumables such as connecting bolts and fasteners, everything is precisely supplied according to design parameters, avoiding delays caused by on-site secondary procurement. During the construction phase, the technical team, combining local regulations and the customer’s usage scenario, customized adjustments to node connections and foundation pre-embedding, ultimately achieving efficient delivery with zero rework and saving the customer more than 20% in overall costs.

Email Us

We offer customized polyurethane sandwich panels with a thickness of 30-250mm, suitable for different building needs.

Our comprehensive shipping system ensures strict inspection from production to delivery, guaranteeing timely delivery.