Types of roof sandwich insulation panels

Roof sandwich insulation panels are lightweight building materials composed of two layers of metal panels with an insulating core in between. They combine load-bearing, thermal insulation, and waterproofing functions, and are widely used in industrial plants, commercial buildings, warehousing and logistics facilities, and residential buildings. Below are some of the most common types of sandwich insulation panels in the global market, along with their core characteristics and application scenarios.

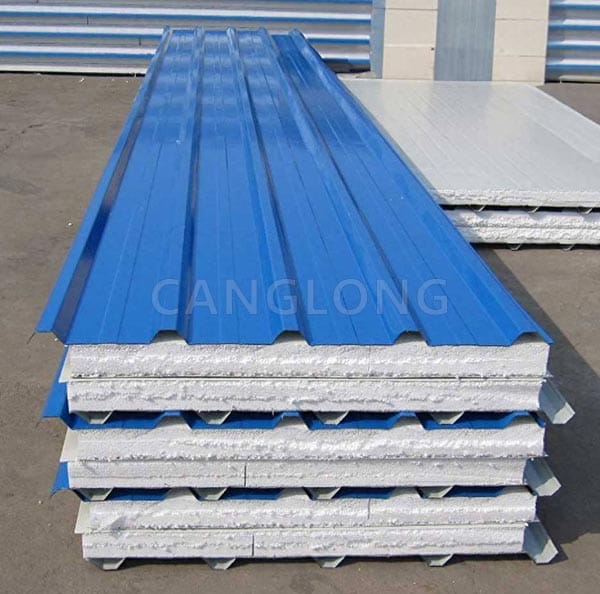

1. EPS Sandwich Panel (Polystyrene Foam Core Material)

Material Composition: Outer layer is color-coated steel sheet/galvanized steel sheet; core material is expanded polystyrene (EPS).

Key Features:

- Thermal Insulation: Thermal conductivity approximately 0.038-0.041 W/(m·K), moderate insulation performance;

- Low Cost: Inexpensive raw materials, mature production process, high cost-effectiveness;

- Lightweight: Density only 18-30 kg/m³, reducing roof load;

- Fire Rating: Typically B2 (combustible), requiring additional fireproofing treatment for enhanced safety;

- Water Resistance: High water absorption rate (approximately 4%), long-term damp environment may affect insulation performance.

Typical Applications: Low-rise factories, temporary buildings, low-cost warehouses, and other scenarios with low insulation requirements but limited budgets.

2. XPS Sandwich Panel (Extruded Polystyrene Foam Core Material)

Material Composition: Outer layer is mostly color steel plate, core material is extruded polystyrene (XPS).

Key Features:

- Superior Thermal Insulation: Dense closed-cell structure with lower thermal conductivity (approximately 0.028-0.032 W/(m·K)), superior moisture resistance compared to EPS;

- Good Compressive Strength: Density 25-45 kg/m³, strong impact resistance, suitable for load-bearing roof applications;

- Fire Rating: Generally B2 (some modifications can reach B1);

- Slightly Higher Cost: More complex manufacturing process than EPS, resulting in a slightly higher price.

Typical Applications: Cold storage, temperature-controlled workshops, warehouses or commercial buildings with high moisture resistance requirements.

3. PU/PIR Sandwich Panel (Polyurethane/Polyisocyanurate Core Material)

Material Composition: Outer layer is color steel plate or stainless steel plate, core material is rigid polyurethane foam (PU) or polyisocyanurate (PIR).

Key Features:

- Top-Tier Insulation: Lowest thermal conductivity (PU approximately 0.022-0.026 W/(m·K), PIR even lower at 0.018-0.023), providing more than twice the insulation performance of EPS for the same thickness;

- High Strength: Density 35-60 kg/m³, excellent compressive and bending resistance, suitable for direct use as a roof load-bearing structure;

- Fire Resistance Optional: Ordinary PU is B2 grade, flame-retardant PIR can reach B1 or even A2 grade (near non-combustible);

- Aging Resistance: Special surface treatment resists ultraviolet rays, with a service life of over 20 years;

- Higher Cost: Raw material and technological barriers are higher than EPS/XPS.

Typical Applications: High-end factories, cold chain logistics centers, data centers, passive ultra-low energy buildings, and other scenarios with stringent insulation requirements.

4. Rock Wool Sandwich Panel (Basalt Fiber Core Material)

Material Composition: The outer layer is a color-coated steel sheet, and the core material is inorganic fiber (rock wool) made from molten basalt.

Key Features:

- Fire Resistance: Class A non-combustible material (highest fire resistance rating), heat resistant up to 600℃ or higher;

- Excellent Sound Insulation: The porous fiber structure effectively blocks noise (sound insulation ≥40dB);

- Moderate Thermal Insulation: Thermal conductivity approximately 0.040-0.045 W/(m·K), slightly lower than EPS;

- Moisture Absorption: Easily absorbs water, leading to a decrease in thermal insulation; requires the use of a waterproof layer;

- Environmentally Friendly and Safe: No formaldehyde release, harmless to the human body.

Typical Applications: Public buildings or industrial facilities with extremely high fire safety requirements, such as chemical plants, power plants, hospitals, and schools.

5. Glass Wool Sandwich Panels (Glass Fiber Core Material)

Material Composition: The outer layer is a color-coated steel sheet, and the core material is inorganic fibers (glass wool) drawn from molten glass.

Key Features:

- Fire Resistance Class A: Similar to rock wool, non-combustible and high-temperature resistant;

- Lightweight and Flexible: Density only 12-48 kg/m³, the core material is flexible, suitable for curved roofs;

- Moderate Thermal Insulation: Thermal conductivity approximately 0.035-0.042 W/(m·K);

- Prone to Shedding: The fibers are relatively soft, and long-term use may cause the surface layer to detach due to vibration, requiring reinforcement and fixation;

- Low Cost: Raw materials are inexpensive, and the price is lower than rock wool.

Typical Applications: Large-span curved roofs such as stadiums and exhibition halls, or fire-resistant buildings where cost is sensitive.

How to Choose?

- Budget priority: Choose EPS (low cost) or glass wool (fireproof + low cost);

- Insulation is paramount: Choose PU/PIR (top-tier insulation);

- Fire resistance is essential: Choose rock wool (Class A non-combustible);

- Moisture resistance and durability: Choose XPS (extruded polystyrene for moisture resistance) or PU (aging resistant).

Regardless of the type of roof sandwich insulation panels, the choice must be based on the specific project’s climate conditions (e.g., higher insulation requirements in cold regions), fire safety standards (e.g., EU EN13501, China GB8624), and service life. In the global market, PU/PIR is gradually becoming mainstream due to its high efficiency and energy saving, while rock wool is irreplaceable in areas with strict fire safety requirements.