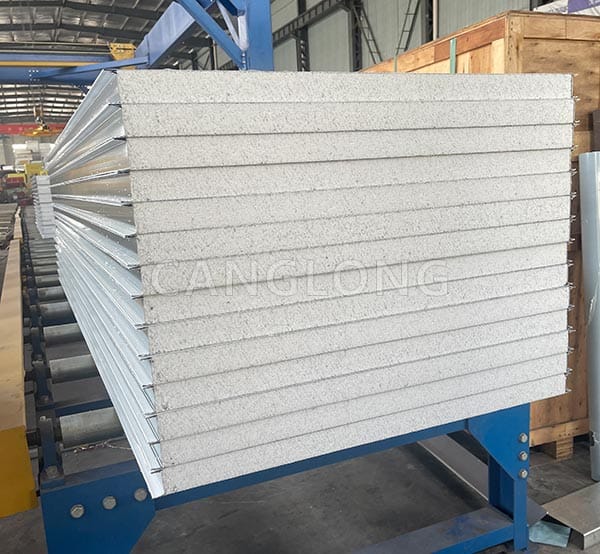

How to build a food factory of more than 3,000㎡ using EPS sandwich panels?

Canglong Group built a 3330㎡ modern food factory for a large Peruvian food company. With efficiency, safety, and cleanliness as its core objectives, the factory innovatively adopted EPS sandwich panels as a key building material, successfully achieving an integrated layout of two workshops. The large workshop (84m×30m×10.6m) and the small workshop (54m×15m×8.6m) are seamlessly connected through a portal frame structure, creating an industrial space that meets stringent food production standards. EPS sandwich panels, with their superior performance, became a core highlight throughout the factory design.

Structural Support and Space Shaping

The main structure of the project uses Q355 H-beams and C-beams to ensure structural strength. EPS sandwich panels, with their lightweight and high-strength characteristics, are deeply integrated into the spatial structure. As the core enclosure material for the roof and walls, their modular installation significantly shortened the construction period. Compared to traditional masonry or concrete pouring, EPS sandwich panels require only simple fixing during on-site splicing, making them particularly suitable for rapid installation in large-span workshops and facilitating early project delivery. Furthermore, the panel thickness can be precisely customized to meet insulation requirements, balancing structural stability and cost-effectiveness.

Clean Production Guarantee

Food factories have extremely high requirements for environmental cleanliness, and the surface treatment process and material properties of EPS sandwich panels perfectly meet this need. The inner walls are treated with a food-grade coating or film, resulting in a smooth, non-porous surface that does not easily absorb dust, microorganisms, or grease. Daily cleaning only requires wiping with water to maintain hygiene. The closed-cell polystyrene foam (EPS) filling inside has strong chemical stability and does not react with food ingredients, eliminating the risk of contamination. In addition, the panel joints are treated with special sealing strips, and the long side walls are reinforced with galvanized steel wire mesh (enhancing wind pressure resistance), effectively blocking external dust and insects from entering, creating a sterile barrier for food production.

Core Environmental Control

Food production often involves temperature and humidity-sensitive processes (such as baking and cold storage pretreatment). The low thermal conductivity (≤0.03W/m·K) of EPS sandwich panel is a key advantage. Its composite structure, with double-sided metal panels and a high-density EPS foam layer in the middle, effectively blocks external high/low temperature conduction and reduces heat loss from the interior. In summer, it can reduce air conditioning load by more than 30%, and in winter, it can reduce heating energy consumption by 25%, significantly lowering operating costs. Actual measurement data shows that the temperature difference within the workshop can be controlled within ±2℃, providing a stable temperature and humidity environment for food processing and ensuring consistent product quality.

Safety and Durability

For the steam and moisture environments that may exist in food factories, EPS sandwich panels undergo flame-retardant modification treatment (achieving B1-level flame-retardant standard). When exposed to fire, they only carbonize without dripping, significantly improving safety when combined with the workshop’s fire protection system. Simultaneously, the galvanized steel or color-coated steel sheet on the surface of the panels has excellent corrosion resistance, resisting humid air and cleaning agent erosion, with a service life of over 20 years, far exceeding that of ordinary masonry walls. Furthermore, the interior ceiling utilizes the same series of EPS sandwich panel which not only maintains the overall clean aesthetic but also avoids the problems of dust accumulation and maintenance difficulties associated with traditional ceilings, further reducing later operation and maintenance costs.

From the rapid construction of dual workshops to long-term stable operation, EPS sandwich panels with their dual advantages of multifunctionality and economy, have become the core support for Canglong Group’s food factory solutions. They not only meet the cleanliness, temperature control, and safety requirements of food production but also improve construction efficiency through modular design, setting a benchmark for green building materials empowering the food industry. In the future, with the upgrading of the food industry, EPS sandwich panels are likely to demonstrate their irreplaceable value in more high-standard factories.