Design a sustainable warehouse using PU insulated sandwich panels

With the explosion of e-commerce and the accelerated operation of supply chains, warehouses are no longer simply storage rooms. They are the heart of the logistics network, a key node for companies to reduce costs and increase efficiency, and a crucial battleground in the fight against climate change.

Have you ever faced this dilemma? Traditional warehouses are as cold as ice cellars in the winter and as scorching as steamers in the summer, with air conditioning running 24/7. Warehouse construction takes three months, a tight deadline and creates dust pollution. After ten years, the walls become moldy and the insulation loses its effectiveness, necessitating a significant renovation expense…

Now, a material called “PU Insulated Sandwich Panel” is redefining the standard for sustainable warehouses. It not only reduces electricity costs for warehouses, but also ensures environmental friendliness from production to recycling, and can even help companies easily obtain international green certifications.

I. What is PU Insulated Sandwich Panels?

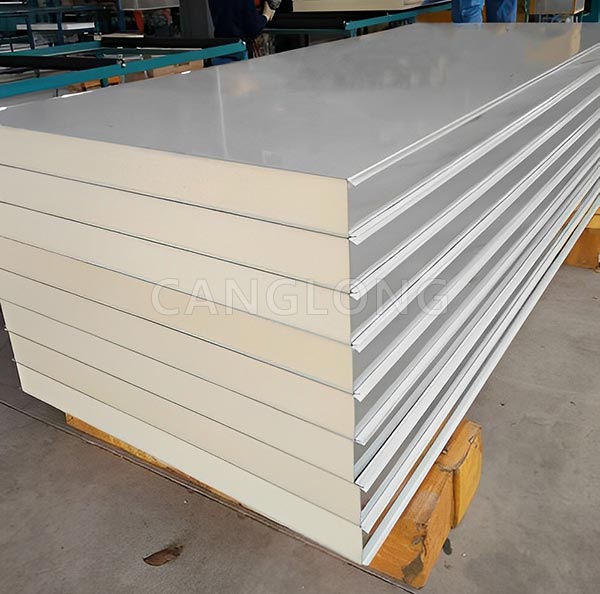

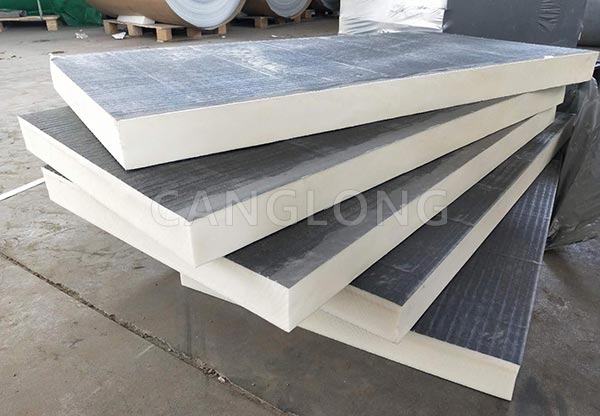

Simply put, it’s a sandwich-structured building material consisting of a layer of polyurethane (PU) foam sandwiched between two metal panels (color-coated steel or aluminum-zinc sheet). Don’t underestimate this 3-5 cm thick “foam”; it’s the heart of a warehouse’s energy efficiency.

- Superb insulation: PU’s thermal conductivity is over 80% lower than traditional brick walls (equivalent to the insulation effect of one PU panel equaling a one-meter-thick brick wall). In winter, cold air from outside is blocked. In summer, solar heat is blocked, maintaining a more stable warehouse temperature and reducing air conditioning/heating energy consumption by 30%-50%.

- Lightweight yet ultra-strong: Although its core is foam, its overall strength rivals that of concrete, offering wind, earthquake, and moisture resistance, and can even withstand forklift collisions. Warehouses are a bustling hub of goods, so durability is crucial.

- Breathable, eco-friendly material: The production process is virtually dust-free and wastewater-free, and after scrapping, it is 100% recyclable, unlike traditional brick walls that become construction waste after demolition. The metal panels are melted and recast, while the PU foam is converted into recycled raw materials.

II. What problems does it solve for businesses?

1. Energy savings

Warehouses are energy-intensive. Taking a 20,000 square meter warehouse at room temperature as an example, traditional warehouses rely on self-insulation and air conditioning within their walls, with annual electricity bills of approximately $110,000 for heating in winter and cooling in summer. Using PU insulated sandwich panels improves insulation performance, reducing electricity bills to under the same conditions to less than $60,000. Over a 10-year lifespan, this translates to a potential savings of $500,000 in photovoltaic costs.

More importantly, it protects goods. Fresh produce warehouses no longer have to worry about damage caused by temperature fluctuations, and precision instrument warehouses are less exposed to the risk of condensation, indirectly reducing damage costs.

2. Fast Construction

Traditional warehouses require foundation construction, wall construction, and insulation, taking anywhere from three to six months. During this time, rent must be paid, and delays can result in missed peak sales seasons. PU sandwich panel warehouses are modularly assembled. Panels are pre-assembled to size in the factory and assembled on-site like building blocks. A 2,000 square meter warehouse can be delivered in just 30 days. A US cross-border e-commerce client once reported, “We originally planned to start production in June, but we were already using it at the end of April, earning an extra $2 million before the shopping season.”

Furthermore, construction was virtually dust- and noise-free, resulting in fewer complaints from surrounding communities and smoother government approvals. This is particularly important in regions with strict environmental regulations, such as Europe and Japan.

3. Reduced Maintenance

After a few years, traditional warehouses experience mold on the walls and water absorption and ineffective insulation, requiring renovation every five years at a cost of tens of thousands of dollars. PU sandwich panels’ metal panels are rust-resistant, and their closed-cell core structure doesn’t absorb water, requiring virtually no maintenance for 10 years. A Brazilian food warehouse owner calculated, “I’ve saved three renovations in 10 years, which is equivalent to saving a year’s electricity bill!”

III. Sustainability is the green passport

Nowadays, global clients choose warehouses based not only on usability but also on compliance with green standards.

EU: To meet CPR, low-carbon emission certification (such as CE-PED) for PU sandwich panels can help you pass quickly. In the United States, high-performance building envelopes are a key LEED certification bonus, and the high R-value (thermal insulation coefficient) of PU sandwich panels maximizes this.

In China, energy conservation and utilization account for 30 points in the green building evaluation criteria, making PU sandwich panels easily a high score.

More importantly, it aligns with the circular economy trend. When the warehouse reaches the end of its life, the dismantled panels can be 100% recycled, with the metal sold and the PU foam recycled, truly achieving zero waste. This is an irreplaceable competitive advantage for ESG-focused multinational companies.

IV. Real Case Studies

Picnic, a Dutch fresh food e-commerce company, built a 100,000 square meter temperature-controlled warehouse using PU sandwich panels, reducing winter heating energy consumption by 40% and annual CO₂ emissions by 2,000 tons, successfully securing a zero-carbon warehouse subsidy from the Dutch government.

Flex, a Vietnamese electronics manufacturer, built a 50,000 square meter warehouse in Ho Chi Minh City, completing it in 35 days, avoiding rainy season delays and saving the equipment purchase cost of an entire production line in just six months of operation. Chinese cross-border e-commerce company Zongteng Group chose PU sandwich panels when building its overseas warehouse in Germany. Its low-carbon properties earned it certification from a local environmental organization, and the green label on customer orders increased conversion rates by 15%.

Conclusion

From saving money to building reputation, from complying with regulations to leading the industry, PU insulated sandwich panels are redefining the value of warehousing. They’re more than just a storage space; they’re a vehicle for companies to communicate their green commitments to the world. If you’re planning a new warehouse or renovating an existing one, consider using PU insulated sandwich panels.

Tip: When choosing PU sandwich panels, remember to pay attention to the core density (recommended ≥40kg/m³), fire rating (minimum B1), and panel corrosion resistance; these factors directly impact long-term performance.