Large Daily Output

Delivery Time: 2025-7-9

Project Name: factory building

50mm polyurethane sandwich wall panel sent to the United States

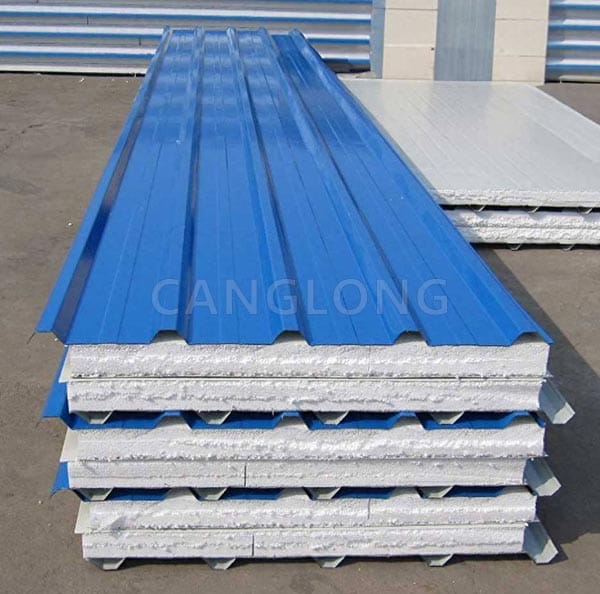

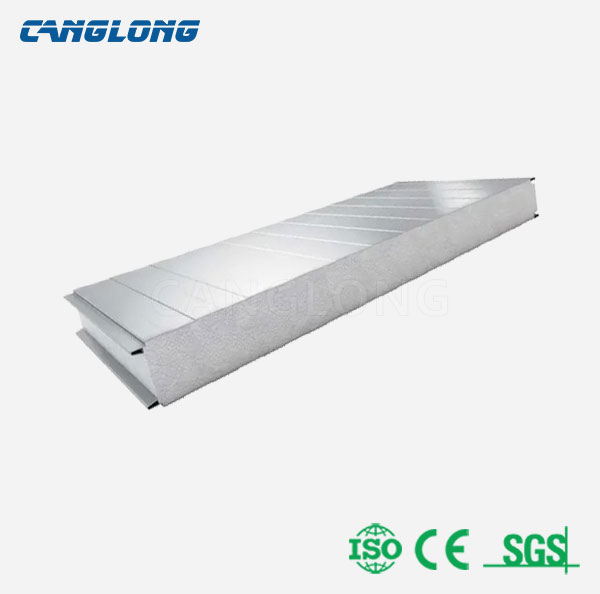

Recently, the 50mm thick polyurethane sandwich wall panel customized by Canglong Group for American food processing companies have been officially packed. 20 thickened pallets are neatly lined up, waiting to be loaded into special containers and cross the Pacific Ocean to North America. This batch of wall panels, which embody the temperature of “China Smart Manufacturing”, not only refreshes the upper limit of thermal insulation performance of similar products with 50mm ultra-thick core materials, but also builds a safe armor for transoceanic transportation through the dual protection design of film wrapping and corner protection.

As a customized product developed by Canglong Group for the needs of the North American market, this batch of 50mm thick polyurethane sandwich wall panel can be said to be born for harsh environments.

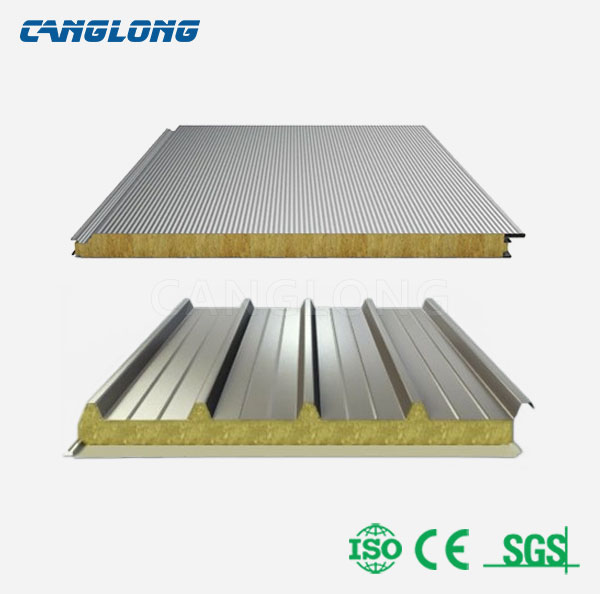

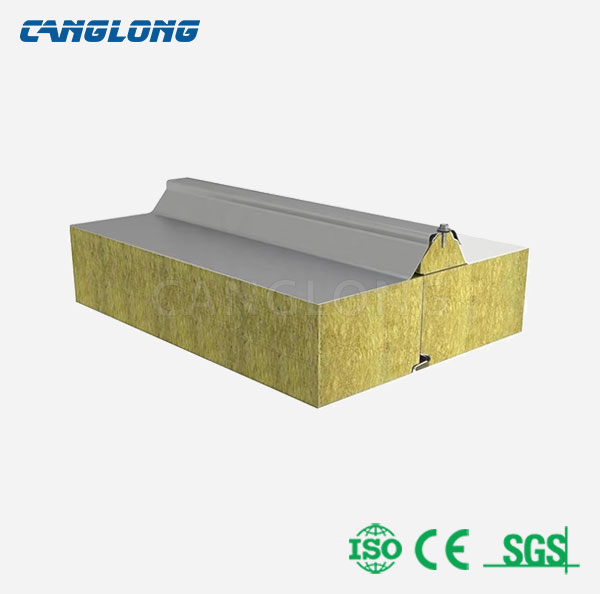

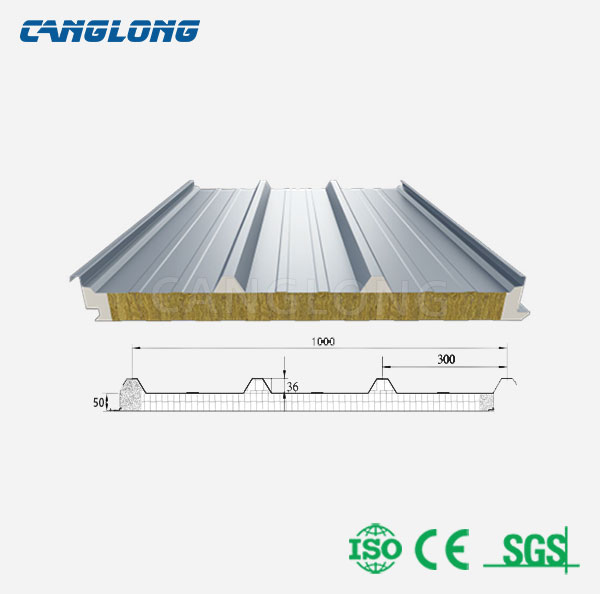

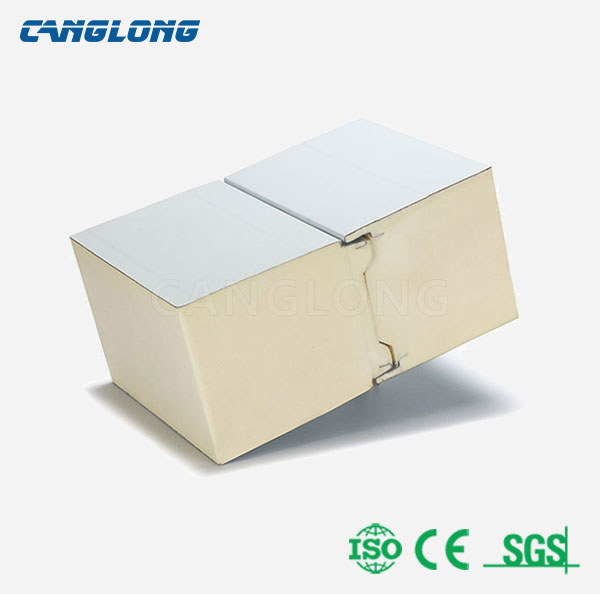

- Insulation, low energy consumption expert: The core material is made of high-density closed-cell polyurethane (thermal conductivity is only 0.024W/(m·K)), combined with double-sided 0.5mm thick aluminum-zinc color steel plate (zinc layer content 180g/㎡), forming a composite structure of metal outer coat and thermal insulation core. According to laboratory tests, in the alternating environment of 40℃ high temperature in summer and -10℃ low temperature in winter in Texas, single-sided wall panels can reduce building energy consumption by 35%, helping customers achieve LEED Gold Green Certification goals.

- Compression and corrosion resistance, durable king: The density of 50mm core material reaches 45kg/m³, while the industry norm is only 35-40kg/m³. Combined with the yield strength of the surface color steel plate of 345MPa, the overall compressive strength of the wall panel exceeds 1.2MPa, which can withstand the impact of industrial scenes such as forklift collision and snow accumulation. The surface aluminum-zinc coating has no red rust for 1000 hours after the salt spray test (5% NaCl solution), which is perfectly suitable for the high humidity and strong salt spray environment in the southeastern coastal areas of the United States.

- Quick assembly, construction efficiency accelerator: The wall panel adopts a tongue-and-groove bite design, which is easy to assemble. The joint gap is ≤2mm. With the lock-type installation process designed by Canglong, a single person can complete the assembly of 20㎡ wall in a single day, which is 5 times more efficient than the traditional masonry process, perfectly matching the customer’s 30-day construction period requirement to complete the factory enclosure.

Considering the challenges of high humidity, bumps, and stacking in transoceanic transportation, Canglong Group customized a triple protection packaging solution for customers, and engraved details into every link.

- Inner layer, moisture-proof film seals and locks water: Each wall panel is wrapped with a 0.1mm thick PE moisture-proof film, which is tightly attached to the edge of the board through a heat shrink process. Antioxidants are added to the film to isolate 9 0% or more water vapor penetration, avoiding the problem of core material moisture absorption and strength reduction caused by container condensation during transportation.

- Middle layer, bubble film cushioning and shock absorption: 3mm thick pearl cotton bubble film is superimposed on the concave and convex tongues and corners of the wall panels and the vulnerable areas of the edges and corners. The dense arrangement of bubbles with a diameter of 8mm can absorb more than 90% of the transportation vibration energy. It can withstand the 2 tons/㎡ pressure during container stacking (far exceeding the conventional stacking load of sea transportation).

- Outer layer, cardboard corner guards and wrapping film: The whole is wrapped with thickened stretch wrapping film for 3 turns to ensure that the 10-layer stacking is not loose or scattered during transportation. No scratches, L-shaped cardboard enclosures are used on all four sides.

From the precise rolling of 50mm thick core materials to the detailed protection of film wrapping and corner guards, Canglong Group has created a set of wind and rain-resistant and more durable industrial enclosure solutions for American customers with a dual-track model of hard-core technology and delicate services. This batch of polyurethane sandwich wall panel across the Pacific will not only build a warm barrier for the Texas food factory, but also write a vivid footnote of details winning for Sino-US capacity cooperation with the quality of Chinese smart manufacturing. Canglong is interpreting the brand promise of “Chinese smart manufacturing, global trust” with the perfect arrival of each wall panel.

Choose Canglong for the best service

Our Shipment

Canglong sandwich panel manufacturer has a complete delivery system, and everything from production completion to packaging and loading will be carried out strictly in accordance with regulations.

Good Raw Materials

Fast Production

Overall Packaging

Fast Delivery

Convenient Unloading

Damage Compensation

Feel free to get in touch

Learn more about this project?