Large Daily Output

Delivery Time: 2025-9-10

Project Name: cold room

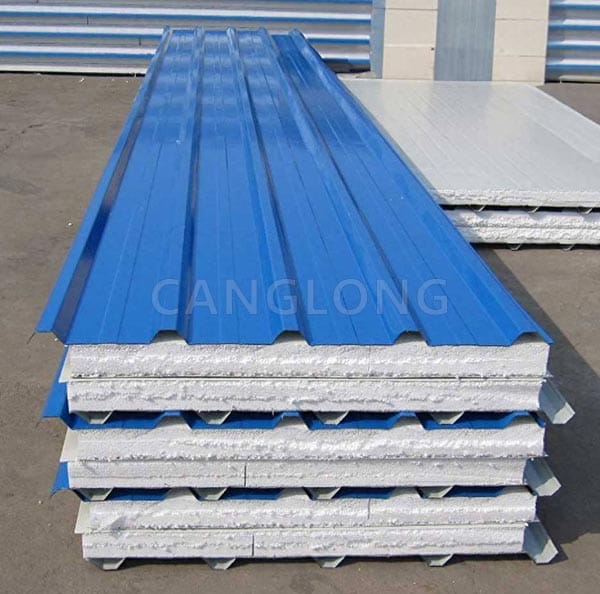

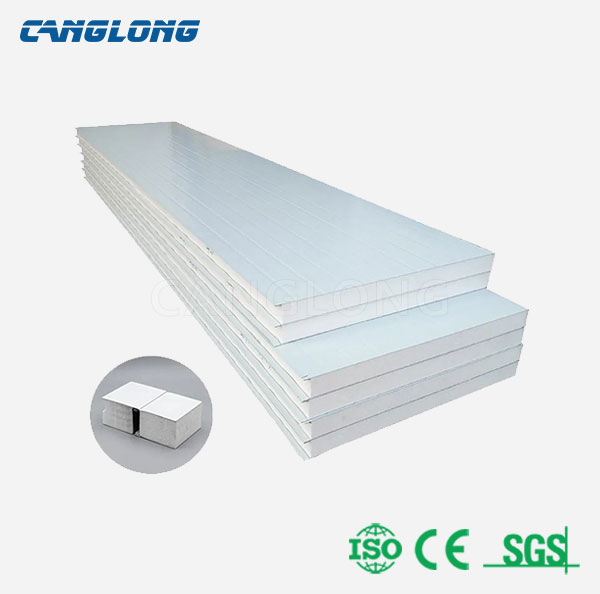

100mm cold storage panels shipped to Indonesia

Canglong Group recently arranged a shipment of 100mm thick polyurethane (PU) cold storage panels, the core insulation material, for a high-standard cold storage project for a client in Indonesia. These 100mm thick PU panels are a premium material specifically designed to meet the stringent requirements of modern, high-efficiency cold storage. Their exceptional performance is primarily demonstrated in the following areas:

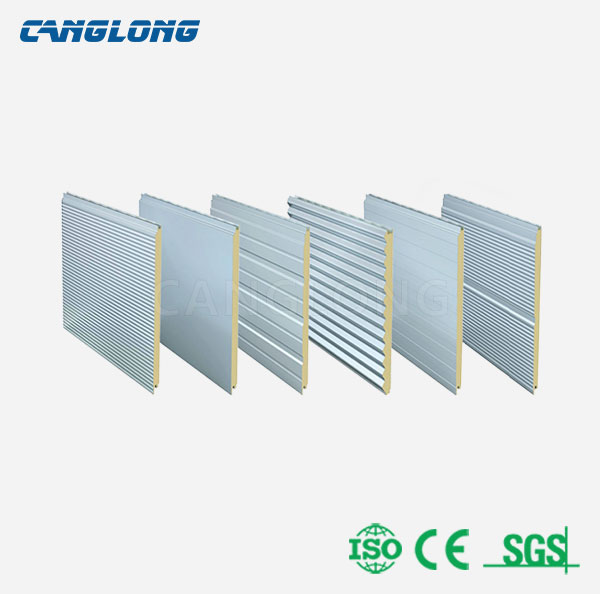

Excellent thermal insulation: Polyurethane has one of the lowest thermal conductivity coefficients of all common insulation materials, meaning it is extremely difficult to transfer heat. Combined with a thickness of 100mm, they form a highly effective and stable thermal barrier. This minimizes heat exchange between the cold storage interior and the tropical environment, ensuring a constant temperature inside the cold storage, significantly reducing refrigeration equipment energy consumption and saving the client long-term operating costs.

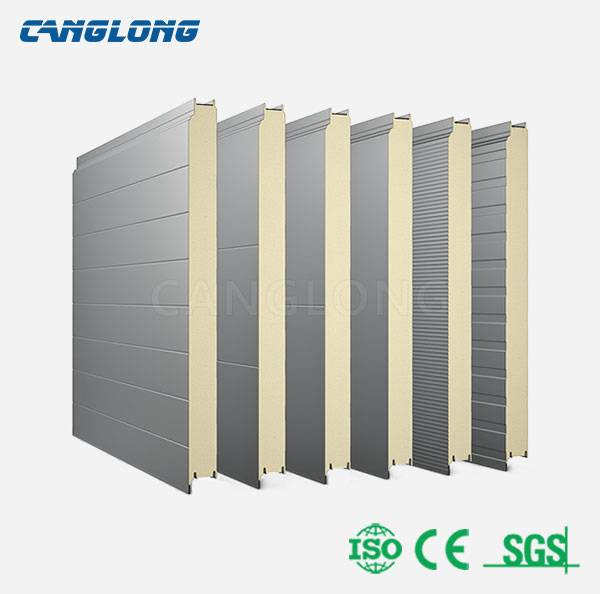

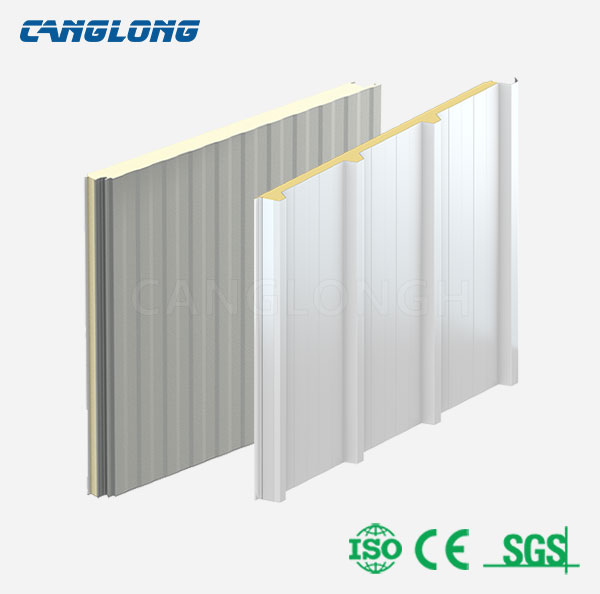

Strong structural strength and durability: These cold storage panels are manufactured using an advanced continuous production process, where polyurethane rigid foam is foamed and formed in a single step between two metal panels, creating a sturdy “sandwich” structure. This results in panels that are not only lightweight but also possess exceptional strength and rigidity, capable of withstanding the various physical impacts of cold storage operations and ensuring overall structural stability and reliability.

Excellent moisture resistance and sealing: Polyurethane foam features a high closed-cell ratio and virtually no water absorption. This property is crucial in Indonesia’s hot and humid climate, effectively preventing water vapor penetration and preventing moisture from causing a sharp drop in insulation performance and equipment corrosion, thereby ensuring the long-term efficient and safe operation of the cold storage.

Easy and hygienic installation: Standard panel edge designs (such as hook-and-groove and tongue-and-groove connections) make installation as quick and precise as building blocks, with tight joints. The panels’ smooth surface resists dust accumulation and is easy to clean, fully meeting the high hygienic requirements of storage environments in industries such as food and pharmaceuticals.

Choose Canglong for the best service

Our Shipment

Canglong sandwich panel manufacturer has a complete delivery system, and everything from production completion to packaging and loading will be carried out strictly in accordance with regulations.

Good Raw Materials

Fast Production

Overall Packaging

Fast Delivery

Convenient Unloading

Damage Compensation

Feel free to get in touch

Learn more about this project?