How to wholesale eps sandwich panel from China factory?

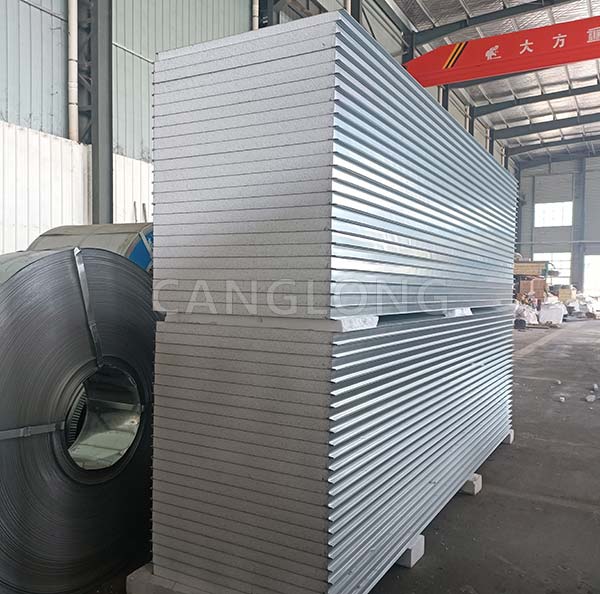

EPS sandwich panels (polystyrene foam sandwich panels) are widely used in building exterior walls, cold storage construction, industrial insulation and other fields due to their light weight, thermal insulation and fireproof properties. As the global manufacturing center, China has thousands of EPS sandwich panel manufacturers, and its products occupy the international market with high cost performance and large-scale supply. This article will deeply analyze how to efficiently connect with China factory, master the core points of wholesale EPS sandwich panel, and help you avoid trade risks and achieve low-cost procurement.

I. 3 core advantages of choosing China factory

Significant cost advantage

The production cost of EPS sandwich panels in China is 30%-50% lower than that in the European and American markets, thanks to a mature industrial chain, low labor and large-scale production. By connecting directly to factories (rather than middlemen), procurement costs can be further reduced.

Outstanding customization ability

China factory support customization of parameters such as EPS density (such as 12kg/m³ to 30kg/m³), board thickness (50mm-200mm), and fire rating (B1/B2 level) to meet the needs of subdivided scenarios such as cold chain logistics and steel structure buildings.

Complete certification system

Mainstream manufacturers have passed international standards such as ISO 9001 quality management system, CE certification, and UL fire certification to ensure that products meet the requirements for market access in Europe and the United States.

II. Key steps and pitfall avoidance guide for wholesale EPS sandwich panel

1. Screen high-quality Chinese EPS sandwich panel manufacturers

Channel recommendation

- B2B platform: Alibaba International Station, Made-in-China.com (screen “EPS sandwich panel manufacturer” or “Chinese factory” label).

- Industry exhibitions: Participate in the Shanghai International Insulation Materials Exhibition and the Canton Fair to inspect the factory’s strength on site.

- Industry associations: Obtain a list of recommended companies through the China Insulation and Energy-saving Materials Association.

Qualification verification

- The factory is required to provide business license, production license, and third-party test report (such as thermal conductivity, compressive strength).

- On-site factory inspection or video factory inspection, focusing on production line equipment (such as fully automatic molding machines) and raw material brands (such as BASF EPS particles).

2. Clarify quality standards and price negotiations

Key points for quality control

- EPS density: Too low can easily cause deformation of the board, it is recommended to choose a flame-retardant board ≥18kg/m³.

- Bond strength: The color steel plate and EPS layer must pass the peeling test to avoid the risk of degumming.

- Fireproof performance: B1 grade (flame retardant) is required for export to Europe, and UL723 certification is required for the North American market.

Price influencing factors

- Raw material fluctuations (EPS particle prices are affected by oil prices).

- Order quantity: Usually, a minimum order quantity of 500 cubic meters or more can enjoy a tiered price, and the account period can be negotiated for long-term cooperation.

3. Logistics and after-sales guarantee

Transportation plan

- Sea transportation is the main method (FOB/CIF terms). Moisture-proof packaging is required when packing. It is recommended to purchase marine insurance.

- International express (DHL/TNT) can be selected for small batch trial orders, but the cost is relatively high.

After-sales service

- Confirm the warranty terms (free replacement if cracking or deformation occurs).

- Require the factory to provide technical support such as CAD drawings and installation guidance videos.

III. Recommended mainstream purchasing areas for EPS sandwich panels in China

Henan/Shandong: Concentrates more than 40% of the national production capacity, with representative companies such as Henan Canglong Group.

Jiangsu/Zhejiang: The Yangtze River Delta region is known for its high-precision equipment and focuses on high-end fireproof panels.

Guangdong/Fujian: Focuses on exporting to the Southeast Asian market, with a short delivery cycle (7-15 days).

IV. Cooperation process and precautions

Inquiry and sample testing: Request free samples to test the thermal insulation and load-bearing capacity of EPS sandwich panels. Signing a contract: clarify MOQ, delivery date, and payment method (30% deposit + 70% final payment).

Production supervision: arrange third-party QC inspection to ensure compliance with order parameters.

Conclusion

Wholesale EPS sandwich panel from China factory requires a balance between cost, quality, and supply chain stability. By accurately screening qualified factories, strictly controlling production links, and optimizing logistics solutions, buyers can significantly increase their profit margins. It is recommended to give priority to Chinese EPS sandwich panel manufacturers that support OEM customization and provide one-stop services to reduce trial and error costs and quickly seize the global market opportunity.