How to lock the low temperature of the cold storage pu panel?

In today’s world of explosive cold chain demand, from beef cold storage in Argentina to fresh flower storage in the Netherlands, from tropical fruit cold chains in Southeast Asia to polar food reserves in Northern Europe, locking in low temperatures has always been the core proposition of cold storage operations. And a seemingly ordinary cold storage pu panel (polyurethane sandwich panel) is actually an invisible temperature magic tool. It uses the simplest principles of physics to construct a three-dimensional defense against heat, making low temperatures as stable as rocks in every inch.

1. Closed cell structure

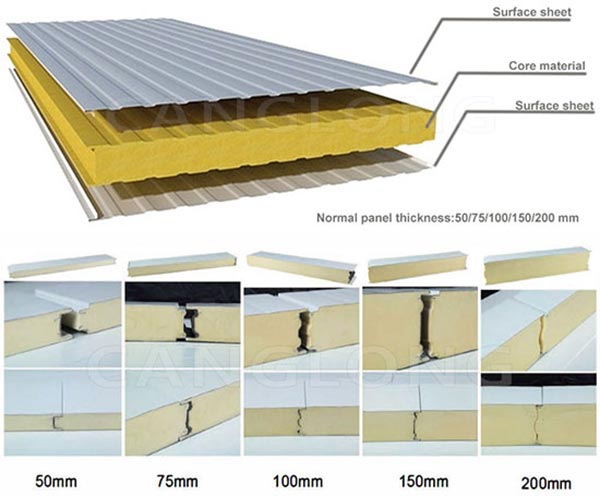

The core secret of PU board is hidden in the core material of its “sandwich” structure. The seemingly lightweight polyurethane foam is actually a honeycomb prison composed of countless micron sized closed pores. These enclosed bubbles with a diameter of only 0.02-0.03 millimeters are arranged independently and tightly together, forming a natural thermal barrier.

When external heat attempts to penetrate the board, the irregular movement of air molecules within the closed cell is restricted. Heat cannot be transferred between bubbles through convection and can only slowly penetrate through thermal conduction. The thermal conductivity of polyurethane itself is as low as 0.022-0.028W/(m · K) (about 1/20 of traditional color steel plates), which is equivalent to wrapping each inch of the board with a layer of insulation down jacket. This closed cell temperature locking feature allows PU panels to maintain stable insulation performance even under extreme temperature differences of -40 ℃ to+80 ℃, making it the first line of defense against low temperatures in cold storage.

2. Structural subtraction

Traditional cold storage insulation often suffers from thickness anxiety. In order to enhance insulation, thicker insulation layers have to be stacked, which sacrifices the space for cold storage and even increases the building’s load-bearing capacity. The high-efficiency insulation gene of cold storage pu panel has broken this dilemma.

Taking a 100mm thick PU panel as an example, its insulation performance is equivalent to 150mm thick EPS (polystyrene board) or 200mm thick rock wool. The advantage of halving the thickness and doubling the insulation allows cold storage designers to increase storage capacity in limited spaces or reduce construction costs with the same capacity.

More importantly, the core material of the cold storage pu panel is integrated with the metal panel (such as color steel plate, aluminum magnesium manganese plate) through continuous foaming technology, without splicing gaps, completely eliminating the common “thermal bridge” vulnerability in traditional splicing insulation. Heat will not sneak into the interior of the cold storage from weak areas such as board seams and screw holes, increasing insulation efficiency by more than 30%.

3. Scene adaptation

The global climate varies greatly, and the low-temperature challenges of cold storage are also different. Cold storage in tropical regions needs to withstand high humidity and high temperature, such as the mango preservation warehouse in Indonesia, where the external humidity often exceeds 80%. Polar cold storage facilities need to withstand extreme cold temperatures of minus 40 ℃, such as Norway’s salmon processing warehouses. The customization ability of cold storage PU board makes it a universal insulation solution that spans climate zones.

- In humid and hot regions: By adding flame retardants, anti mold coatings, or double-sided aluminum foil, PU panels can prevent external humid and hot air from penetrating and prevent internal condensation from frosting (condensation is a hidden killer of cold storage and can damage the insulation layer structure).

- Cold regions/plateaus: High density PU core materials (such as 40kg/m ³ or more) are selected, combined with reinforced metal panels, to resist the brittleness of the board caused by strong winds and low temperatures, ensuring toughness even in an environment of -50 ℃.

- Constant temperature and humidity warehouse (such as pharmaceutical cold chain): By surface embossing treatment or adding nano antibacterial layer, the cold storage pu panel can reduce surface condensation and inhibit microbial growth, meeting the strict requirements of GMP.

4. Full lifecycle

For users, locking in low temperatures is not only a technical issue, but also an economic problem. The long lifespan and low maintenance characteristics of cold storage pu panel allow it to continuously release value throughout the entire lifecycle of the cold storage.

- Easy installation: PU panel has a light weight (about 3-5kg/㎡) and high strength (flexural strength ≥ 0.5MPa). It can be cut and drilled on site without the need for complex tools, and the installation efficiency is 50% higher than traditional insulation materials.

- Low maintenance cost: the surface metal layer is anti-aging, UV resistant, and has no obvious performance degradation after 15-20 years of normal use, avoiding the additional expense of frequent replacement of the insulation layer.

- Recycling and reuse: Waste cold storage pu panel can be 100% recycled and processed into insulation materials or other industrial products, meeting the green cold chain requirements of the global “dual carbon” trend.

Conclusion

From durian cold storage in Southeast Asia to lobster storage in Canada, from pharmaceutical cold chains in the Middle East to dairy production bases in Northern Europe, cold storage pu panels have become the low-temperature guardians of cold storage with their physical intelligence of closed cell temperature locking, engineering ingenuity of structural subtraction, flexible strategies for scene adaptation, and full lifecycle economy. It may not have a glamorous technological halo, but it innovates with the most fundamental materials, making the big task of “locking in low temperatures” simple, reliable, and sustainable.