Why choose pu foam edge sealing rock wool sandwich panel for the external wall of the plant?

In recent years, the construction of industrial plants has been upgrading from meeting functional requirements to being efficient, green, and sustainable. As the protective coating of the factory building, the choice of external wall enclosure system directly affects the energy consumption, lifespan, and safety of the building. In recent years, PU foam edge sealing rock wool sandwich panel has rapidly become the best choice for the external wall of industrial plants worldwide with its triple advantages of heat preservation, fire prevention and weather resistance.

Ⅰ. Why do PU foam edge sealing rock wool sandwich panels become rigid?

1.1 Policies and Standards

The major economies around the world have formed a consensus on green buildings: the European Union’s EPBD requires all new buildings built after 2030 to meet the “zero carbon” standard. The LEED certification in the United States includes the thermal performance of the enclosure system as a core scoring item. China’s “Industrial Green Development Plan” states the goal of reducing energy consumption per unit area of industrial buildings by 15%. Traditional EPS (polystyrene) sandwich panels are difficult to meet high standard requirements due to their low fire rating (B1 level) and aging insulation layer (lifespan of only 10-15 years). The PU foam edge bonding rock wool sandwich panel has a Class A fireproof performance (non combustible) and a thermal conductivity as low as 0.038W/(m · K) (30% lower than EPS), which just fits the policy of high energy conservation and high safety.

1.2 Frequent occurrence of extreme weather conditions

Global warming has led to an increase in extreme weather: the once-in-a-century snowstorm in North America, the continuous high temperature heat wave in Europe, the strong wind and rainstorm in the typhoon season in Southeast Asia… The sealant strips of traditional sandwich panels are prone to aging and cracking, rainwater penetration will accelerate the corrosion of steel plates, and the thermal performance of the insulation layer will drop sharply after water absorption. PU foam edge sealing technology improves the tightness of plate joints by 80% through high-density polyurethane foam+elastic sealing layer. With the hydrophobicity of rock wool core material (water absorption<1%), it can maintain stable thermal insulation and structural strength even in the face of extreme environments such as rainstorm and snowstorm. This characteristic makes its application rate in extremely cold/high temperature industrial plants in Europe (such as Germany, Sweden) and North America (such as Canada, Alaska) exceed 60%.

1.3 Better long-term costs

The comprehensive consideration of initial investment and long-term operation and maintenance costs is the key for industrial enterprises to choose enclosure materials. Although the unit price of PU foam edge bonding rock wool sandwich board is slightly higher than that of ordinary EPS board (about 15% -20%), its service life of more than 25 years (twice that of EPS), energy saving income of more than 30% (wall heat dissipation accounts for about 20% of the annual power consumption of industrial plants), and maintenance cost of frequent renovation free have reduced its life cycle cost by more than 35%. According to the data of Global Market Insights, an international building materials consultancy, the global market size of high-performance sandwich panels for industrial plants will reach 4.5 billion dollars in 2023, of which the proportion of PU foam edge sealing rock wool panels will exceed 40%, and it is expected to exceed 8 billion dollars in 2030.

Ⅱ. How does Chinese intelligent manufacturing define the new benchmark for global sandwich panels?

On the global PU foam edge sealing rock wool sandwich panel track, Chinese enterprises are particularly outstanding. Among them, Canglong Group has become the preferred supplier for industrial plants in Europe, Southeast Asia, the Middle East and other regions with its three core advantages of technology research and development, intelligent manufacturing, and customized services.

2.1 Technical barriers

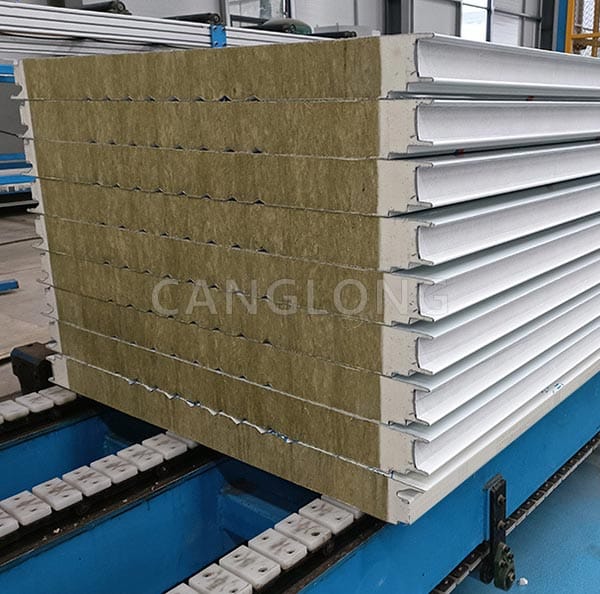

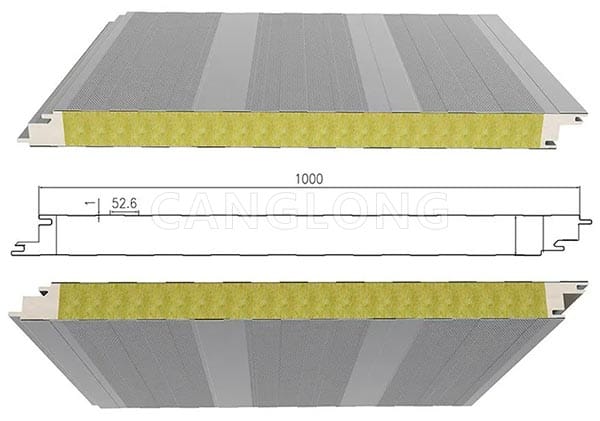

The key of PU foam edge sealing is precise foaming and uniform fitting. Insufficient density of foam will lead to poor sealing performance, and too high density will lead to cracking. Insufficient bonding strength between the edge sealing layer and rock wool or steel plate can cause delamination and detachment. Canglong Group controlled the density deviation of PU foam at ± 2kg/m ³ (industry average ± 8kg/m ³) and improved the bonding strength to 0.15MPa (national standard is 0.1MPa) by using the dynamic temperature control foaming process and monitoring the foaming temperature, pressure and flow rate in real time. And it has passed the EU CE and German T Ü V fire certification, becoming one of the few Chinese technology solutions that can compete with German and Japanese brands on the same stage.

2.2 Intelligent manufacturing

Canglong Group has deployed 12 fully automated production lines in its intelligent factory in Xinxiang, Henan. The laser cutting system has an error of ≤ 0.1mm to ensure accurate sheet size. Real time monitoring of the foaming process using an online infrared thermal imaging device, with automatic removal of defective products. The ERP system connects the entire process of orders, production, and logistics, with a on-time delivery rate of over 98%. Canglong will verify the performance of the board in advance to ensure that it meets the standards upon delivery.

2.3 Customized services

Canglong provides PU foam edge sealing rock wool sandwich panels with different thicknesses, including 50mm, 75mm, 100mm, 150mm and 200mm. We will also choose sandwich panels of different thicknesses according to the project situation. In 2023, Canglong will supply 80mm thick 5000 ㎡ PU foam edge sealing rock wool sandwich panels for a cold chain logistics park in Iceland, which will ensure thermal insulation in cold weather and save costs.

Conclusion

When the global industrial plants are transferred from extensive construction to fine operation, PU foam edge sealing rock wool sandwich panel has changed from optional material to mandatory configuration. Canglong Group, with its technological innovation and global layout, has not only won international reputation for Chinese manufacturing, but also become the Chinese benchmark for global industrial plant enclosure systems with more reliable performance, better cost, and customized services.

For enterprises planning to build or renovate plants, choosing Canglong Group’s PU foam edge sealing rock wool sandwich panel is not only to choose a good wall panel, but also to plant a green seed for long-term energy conservation, safety and competitiveness of the factory.