High temperature resistant & fireproof sandwich panels protect photovoltaic/lithium battery plant

Under the global energy transition wave, the photovoltaic and lithium battery industries are experiencing explosive growth. However, the high energy consumption and storage characteristics of these two industries also make factory safety a top priority. A fire can cause tens of millions of losses or even casualties, and high-temperature resistant and fireproof sandwich panels are the key materials to mitigate this risk.

1. Why do photovoltaic/lithium battery factories need fire prevention?

Hidden dangers of lithium batteries: The electrolyte and positive electrode materials in lithium battery production are prone to decomposition when exposed to high temperatures, releasing flammable gases that are difficult to extinguish in the event of a fire.

Photovoltaic risks: The purification of silicon materials and packaging of components involve high-temperature processes, and large areas of roofs are prone to heat accumulation.

Policy and regulations: The EU’s “New Battery Law”, China’s GB50016-2014 and other regulations continue to upgrade the fire protection level requirements for industrial buildings, and A-level fire-resistant materials have become a must-have.

2. Triple protection advantages of high-temperature resistant and fire-resistant sandwich panels

Extreme heat resistance, guarding the safety bottom line

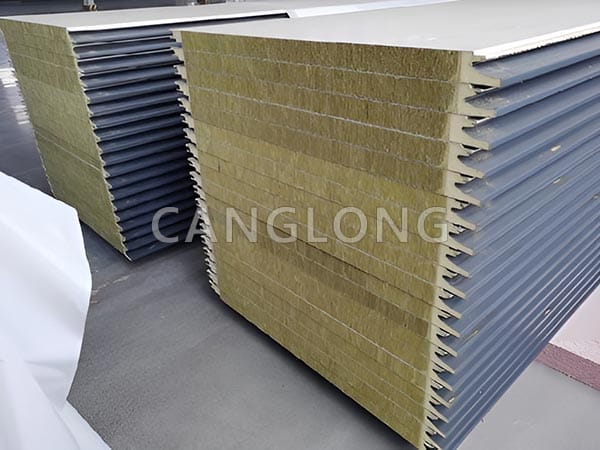

Inorganic core materials such as rock wool/glass wool can withstand high temperatures above 800 ℃, far exceeding the 200 ℃ limit of ordinary foam core materials. Do not release toxic smoke in case of fire, and strive for golden time for personnel evacuation and firefighting rescue. A case study of a leading lithium battery company shows that after using this type of board in its battery cell workshop, the fire resistance limit has been increased to 2 hours, far exceeding industry standards.

Accurate temperature control helps stabilize production

The thermal conductivity of the core material is as low as 0.04W/(m · K), and when combined with double-sided metal panels, it can achieve ± 2 ℃ constant temperature control. Especially suitable for environmentally sensitive production processes such as photovoltaic silicon wafer cutting and lithium electrochemical conversion, reducing the decrease in yield caused by temperature fluctuations.

Lightweight and efficient, suitable for rapid production expansion

Compared to traditional concrete partition walls, sandwich panels reduce weight by 70% and increase installation efficiency by 50%, perfectly matching the rapid capacity expansion needs of photovoltaic/lithium battery enterprises. A photovoltaic industrial park in Southeast Asia used modular sandwich panels to build workshops and completed the construction of a 20000 square meter factory building in just 30 days.

3. Material Innovation under Global Trends

European market: driven by the EN13501-1 standard, the demand for A2 level fireproof sandwich panels have surged. The nano aerogel composite panel launched by a German enterprise has been applied to the Tesla Berlin Super Factory.

Asia Pacific Innovation: Chinese companies have developed ceramic fiber-reinforced sandwich panels that have exceeded the temperature limit of 1200 ℃ and have been certified by top customers such as LG New Energy and CATL in South Korea.

Green certification: LEED, BREEAM and other green building systems incorporate fire performance into their ratings, promoting the popularization of recyclable aluminum magnesium manganese panel sandwich panels.

4. Selection suggestions

Only focus on fire rating and ignore smoke toxicity: prioritize products that meet GB8624-2012 Class A and ASTM E84 Class A standards.

Blindly pursuing low prices: Poor quality core materials are prone to water absorption and deformation. It is recommended to choose rock wool/glass wool core materials with a density of ≥ 120kg/m ³.

Ignore customized requirements: Choose special models with ventilation slots and explosion vents based on workshop processes (such as explosion-proof design for lithium battery injection areas).

Conclusion

As the installed capacity of photovoltaics grows at an annual rate of 30%, and as the production capacity of power batteries advances towards the TWh era, factory safety has shifted from a cost item to a competitive advantage. High temperature resistant and fireproof sandwich panels, with their triple value of fire prevention, energy saving, and high efficiency, are becoming a standard configuration for new energy factories worldwide. Choosing a fire rated panel that meets international standards and adapts to production processes is not only a compliance requirement, but also an investment in the lifeline of the enterprise.