Can EPS insulation metal panels be used in cleanroom?

In the biological drug production workshop of Roche Pharmaceuticals in Switzerland, the wall was contaminated by drugs due to the shedding of fibers from traditional insulation materials. In a semiconductor chip factory in the United States, the wall cracked due to thermal expansion and contraction of the insulation layer, and the cleanliness level dropped from ISO 5 (100) to ISO 7 (10,000). In a food processing plant in Saudi Arabia, high temperatures in summer caused energy consumption in the cold storage area to soar by 30%. The typical concerns of these cleanroom point to a core issue: How to find insulation materials that balance performance and cost under high standards of dust prevention, temperature control, and moisture resistance?

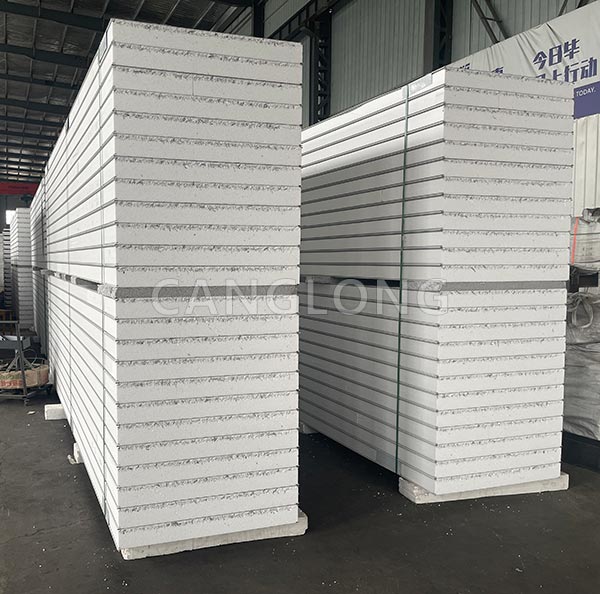

The emergence of EPS insulation metal panels, with its fiber-free, low precipitation, and high stability, is becoming an insulation material for cleanroom. It not only meets the stringent requirements of clean environments, but also becomes a clean space optimizer for global pharmaceutical, electronics, food, medical and other industries through modular design and global adaptability.

1. Core requirements of clean room

The design of cleanrooms must meet ISO 14644 standards (particle concentration classification), and at the same time have strict requirements on indicators such as temperature and humidity (±0.5℃/±2%RH), pressure difference (5-15Pa), and microorganisms (settled bacteria ≤1CFU/dish). The core challenge is how to maintain a stable microenvironment in a dynamic environment. Traditional insulation materials (such as rock wool, glass wool, and polyurethane) are often difficult to adapt to clean scenes due to problems such as fiber shedding, strong hygroscopicity, and fire hazards. The EPS insulation metal panel has achieved a deep fit with clean requirements through the triple innovation of materials, structure, and process.

1.1 Material properties

The first taboo of cleanroom is particulate pollution. Rock wool fibers (diameter 3-5μm) are easily shed under the impact of airflow and float in the air to become microbial carriers. Polyurethane foam may release volatile organic compounds (VOCs), affecting the purity of drugs or electronic components. The advantages of EPS insulation metal panels are:

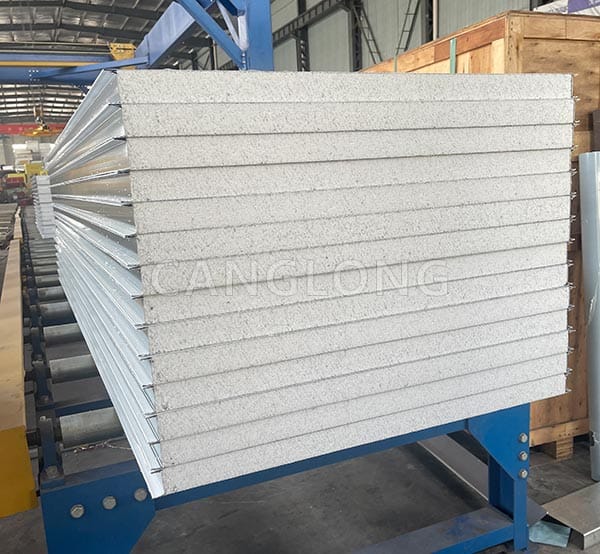

- Pure material: EPS is made of polystyrene (PS) foam, with stable chemical properties, no fiber, no dust precipitation. After testing, the friction coefficient of EPS surface is ≤0.02, which is much lower than the 0.5-0.8 of rock wool.

- Dense surface: The metal panel (color steel plate, stainless steel plate or aluminum alloy plate) is formed by continuous rolling, and the surface has no pores (roughness Ra≤0.8μm), which is not easy to absorb dust. When cleaning, just wipe it to restore it to cleanliness.

- Low precipitation: EPS itself does not contain harmful substances such as formaldehyde and benzene. There is no decomposition gas release under high temperature (below 80℃) environment, which meets the FDA (US Food and Drug Administration) 21 CFR 177.1640 standard for food contact materials.

1.2 Structural design

The temperature and humidity fluctuations in cleanrooms are often caused by the thermal bridge effect. Local cold/hot spots are easily formed at the joints between the traditional insulation layer and the metal frame and wall, resulting in condensation (affecting the growth of microorganisms) or temperature deviation (affecting process stability). EPS insulation metal panels eliminate thermal bridges through an integrated composite structure:

- Metal panel + EPS core material: The metal plate and EPS are tightly combined through adhesives or mechanical fixation to form a continuous insulation layer to avoid interface thermal resistance.

- Broken bridge treatment: The edge of the metal plate adopts a tongue-and-groove bite or sealing strip design to block the penetration of hot and cold air through the plate seams. Insulation strips (such as EPDM rubber strips) can be installed at key nodes (such as around doors and windows) to further reduce heat loss.

1.3 Adapt to the needs of multiple scenarios

In addition to basic insulation, EPS insulation metal panels can also meet the additional needs of clean rooms through surface treatment and structural optimization:

- Moisture-proof and antibacterial: Metal panels can be optionally galvanized (corrosion resistance is 3 times that of ordinary color steel) or 304 stainless steel, and EPS core materials are added with flame retardants (such as hexabromocyclododecane, flame retardant grade B1). The surface can be coated with anti-mildew coating (such as water-based polyurethane, antibacterial rate ≥ 99%), suitable for high humidity environments (such as cleaning areas in pharmaceutical workshops).

- Antistatic: The metal panel has a built-in conductive carbon black coating (surface resistivity ≤ 10⁹Ω), or is compounded with anti-static color steel plates to avoid adsorption of particles due to static electricity, suitable for electronic chip workshops.

- Quick installation: The panels are spliced with tongue and groove or snap-on connection, and it only takes 15 minutes to install a single panel, reducing the impact of construction dust on the clean environment.

2. EPS thickness selection in different climate zones

The thickness of EPS insulation metal panels in cleanroom needs to be determined comprehensively based on the three factors of regional climate, cleanliness level and functional requirements. The following are the thickness recommendations and verification data for three typical scenarios in the world:

2.1 Tropical/subtropical high humidity areas (such as Southeast Asia and South America)

Climate characteristics: annual average temperature 25-35℃, relative humidity>80%, high proportion of cooling energy consumption in summer, accounting for about 60% of annual energy consumption.

Demand difficulties: Efficient insulation is required to reduce air conditioning load, while avoiding EPS moisture absorption leading to reduced insulation performance. EPS water absorption rate ≤0.2%, much lower than 1-2% of rock wool.

Thickness recommendation: 50-80mm.

Verification case: A pharmaceutical factory in Bangalore, India (ISO 7 clean room), uses 60mm thick EPS insulation metal panels (surface aluminum-zinc color steel plate), the workshop temperature is stable at 24±1℃ in summer (fluctuation ±3℃ before installation), and the cooling energy consumption is reduced by 28%. After 1 year of monitoring, the moisture absorption rate of EPS core material is only 0.12%, and there is no mildew phenomenon.

2.2 Temperate monsoon area (such as Europe and the Midwest of the United States)

Climate characteristics: low temperature in winter (-10℃ to -20℃), high temperature in summer (30-35℃), large temperature difference between day and night (up to 15℃).

Demand difficulties: It is necessary to take into account winter insulation (reducing heat loss) and summer insulation (reducing heat gain), while meeting the constant temperature accuracy of the clean workshop (±0.5℃).

Thickness recommendation: 80-100mm.

Verification case: An electronic chip factory in Munich, Germany (ISO 5 clean room) uses 100mm thick EPS insulation metal panel (surface stainless steel plate). The temperature fluctuation of the workshop in winter is ≤0.8℃ (≥2℃ before installation), and the air conditioning opening time in summer is shortened by 35%. After 5 years of operation, there is no cracking on the surface of the board, and the insulation performance decay is <5%.

2.3 Frigid zone/high altitude area (such as Siberia, Russia, Sweden)

Climate characteristics: Extremely low temperature in winter (below -40℃), heating period up to 6-8 months, walls are prone to cracking due to freeze-thaw cycles.

Demand pain points: High thermal insulation performance is required to reduce heating energy consumption, and the material must be resistant to freeze-thaw, and EPS remains elastic at -50℃.

Thickness recommendation: 100-120mm.

Verification case: A food processing plant in Yakutsk, Russia (ISO 8 clean workshop) uses 120mm thick EPS insulation metal panel (surface PE film covering anti-icing), the indoor temperature in winter is stable at 18±1℃ (outdoor -45℃), there is no condensation on the wall, no frost heave cracks. After 3 years of testing, the compression strength retention rate of EPS core material is >90% (initial value ≥15kPa).

Clean Room

3. Controversy and breakthroughs

Despite the significant advantages of EPS insulation metal panels, some users still have doubts: “Is EPS flammable?” “Will it age after long-term use?” “Will it damage the surface during cleaning?” In response to these problems, the industry has provided solutions through technological innovation:

Fire protection upgrade: By adding intumescent flame retardants (such as ammonium polyphosphate APP), EPS can achieve B1 flame retardancy (self-extinguishing 3 seconds away from the fire), meeting the fire protection requirements of most cleanrooms (such as China GB 50016-2014 stipulates that the fire resistance level of clean room is ≥ Level 2). If a higher fire protection level (such as Class A) is required, EPS and rock wool composite panels (rock wool layer thickness ≥ 50mm) can be used.

Improved weather resistance: The metal panel surface is coated with fluorocarbon coating (weather resistance ≥ 25 years), and antioxidants (such as hindered phenols) are added to the EPS core material to resist ultraviolet radiation. After 5000 hours of aging test, the tensile strength retention rate is >80%.

Easy-to-clean design: The metal panel can be brushed or ceramic coated (surface hardness HV ≥ 4H), which is scratch-resistant. The density of EPS core material is ≥ 20kg/m³, which is more impact-resistant and has no dents when hit by a falling ball at a height of 1 meter.

4. Conclusion

From the sterile environment of pharmaceutical workshops to the precision manufacturing of electronic workshops, from the hygiene standards of food factories to the biosafety of medical laboratories, EPS insulation metal panels are becoming the preferred material for upgrading cleanrooms around the world with their particle-free, low-energy consumption and easy maintenance characteristics. The choice of its thickness needs to be combined with the regional climate and cleanliness level. On the premise of meeting the insulation requirements, choose the optimal solution that can balance cost, reliability and functional expansion.

Today, as the clean industry transforms towards high precision, low energy consumption and zero pollution, EPS insulation metal panels are not only an insulation material, but also a bridge connecting process requirements and environmental control. It uses industrial precision to create a breathing protective shell for clean room, making every production more secure and every degree of energy consumption more worthwhile.

Choosing EPS insulation metal panels means injecting stable genes into the cleanroom, a clean space solution that can withstand temperature fluctuations, pollution risks, and the test of time.