Large Daily Output

Delivery Time: 2025-4-28

Project Name: house

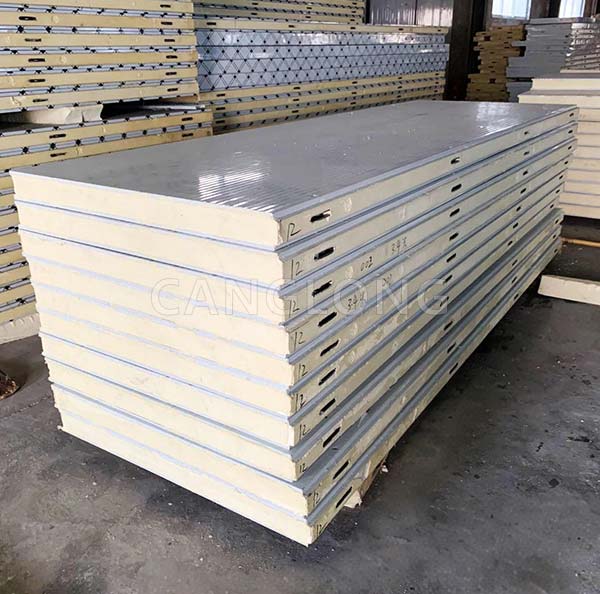

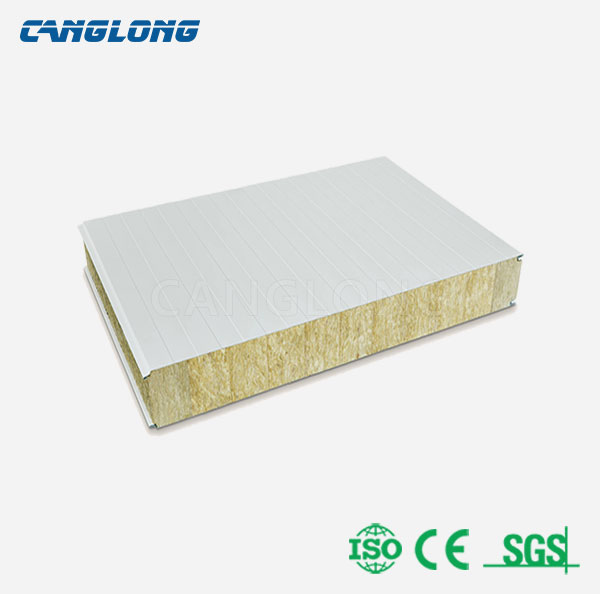

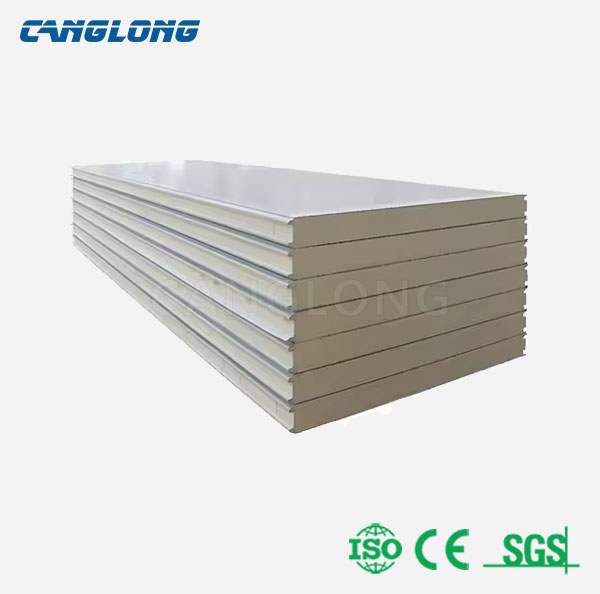

100mm polyurethane wall panels and square tubes shipped to Peru

The 100mm polyurethane wall panels and matching square tubes customized by Canglong Group have been successfully shipped to Peru. This batch of industrial building materials made in China is building a solid quality foundation for the living needs of Peruvian customers with hard-core performance.

Why 100mm polyurethane wall panels? Customized protection under the Peruvian climate

Peru straddles the equator and the southern hemisphere. The project site has both the high temperature and high humidity of the tropical plateau and the temperature difference between day and night in the Andes Mountains, which puts forward strict requirements on the thermal insulation, moisture resistance, corrosion resistance and structural strength of housing building materials. After field research, the technical team of Canglong Group specially selected 100mm thick polyurethane sandwich panels. This is not a simple upgrade of the standard configuration, but a precise solution to the pain points of Peruvian climate.

The three advantages of 100mm PU sandwich panels directly meet the needs of Peruvian projects

1. Super strong insulation

The thermal conductivity of polyurethane is only 0.022-0.027W/(m·K) (about 1/20 of traditional brick walls), and the thickness of 100mm makes its insulation layer thickness and efficiency reach the golden ratio. According to calculations, the heat transfer coefficient (K value) of the sandwich panel is ≤0.45W/(㎡·K), far exceeding the 0.6W/(㎡·K) required by the Peruvian building code. Whether it is the scorching sun of the tropical plateau or the cold and humid invasion of the mountain wind at night, the temperature fluctuation inside the house can be controlled within ±3℃, greatly reducing the energy consumption of air conditioning and saving long-term use costs for residents.

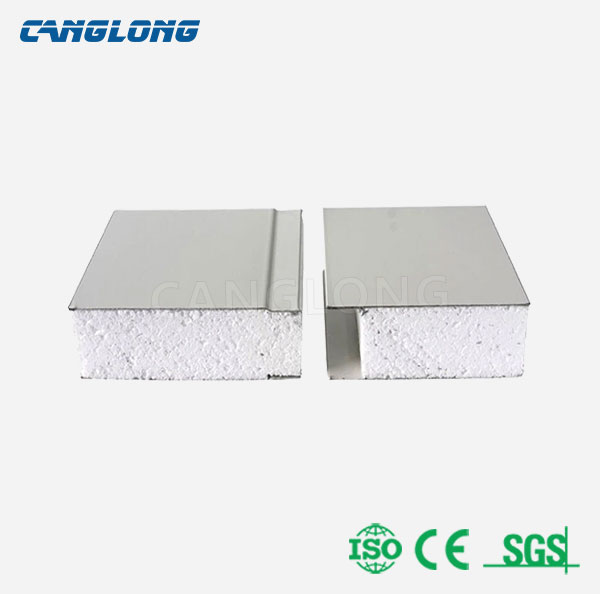

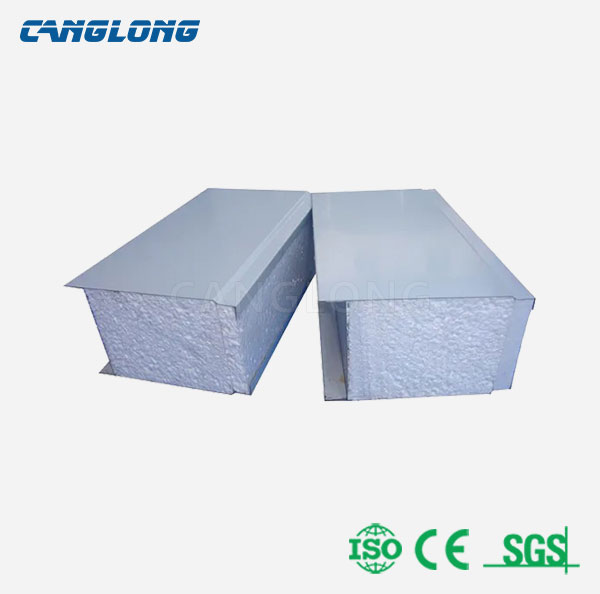

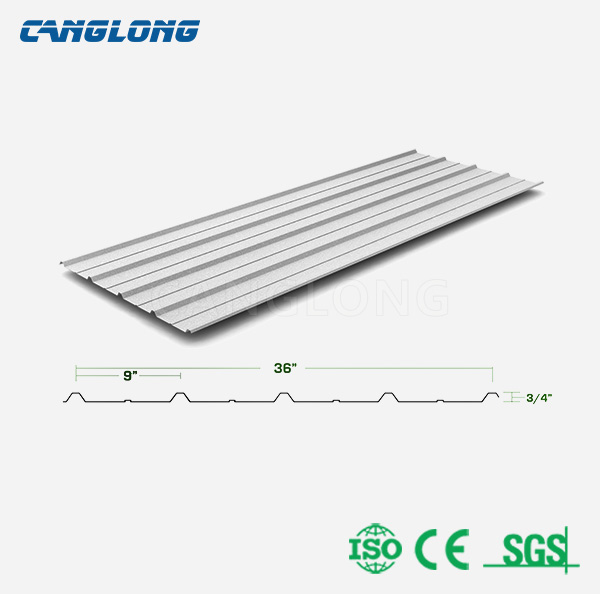

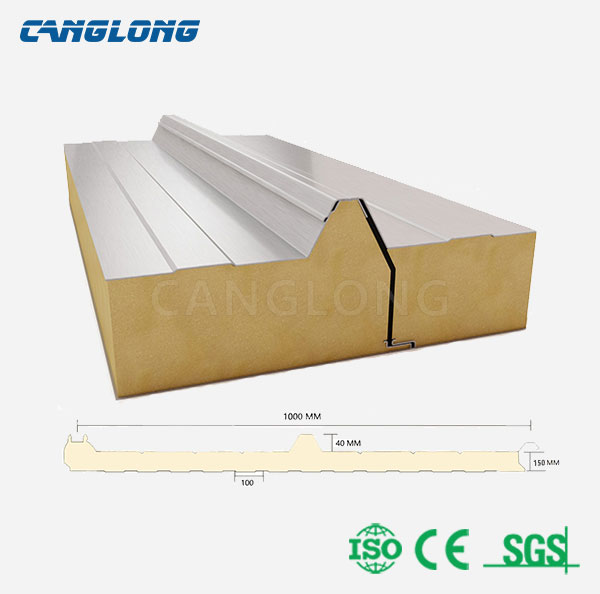

2. Structural toughness

The outer layer of the sandwich panel adopts 0.5mm thick aluminum-zinc-plated color steel plate (yield strength ≥345MPa), and the inner layer and the polyurethane core material are compounded through a continuous foaming process to form a double protection of “metal guard plate + high-elastic foam”. The 100mm thickness not only improves the overall compressive strength (uniformly distributed load ≥1.2kN/㎡), but also improves the wind resistance of the wall by 30% through the patented lock edge tongue and groove design (board seam bite depth 8mm). The coastal areas of Peru are often attacked by hurricanes. This design can effectively resist winds above level 10 and ensure the safety of the house structure.

3. Weather resistance and durability

In view of the high humidity and salt spray environment in some parts of Peru (such as the coastal city of Lima), Canglong Group has carried out triple protection and strengthening of sandwich panels. The outer color steel plate is added with a weather-resistant coating (salt spray test ≥1000 hours), the core material density is increased to 45kg/m³ (ordinary sandwich panels are only 38-42kg/m³), and the board seams are additionally filled with waterproof sealant. After laboratory accelerated aging tests, its service life can reach more than 15 years, far exceeding the 8-10 year cycle of local ordinary color steel plates, greatly reducing the frequency of later maintenance.

Choose Canglong for the best service

Our Shipment

Canglong sandwich panel manufacturer has a complete delivery system, and everything from production completion to packaging and loading will be carried out strictly in accordance with regulations.

Good Raw Materials

Fast Production

Overall Packaging

Fast Delivery

Convenient Unloading

Damage Compensation

Feel free to get in touch

Learn more about this project?